The ball mill is the key equipment for crushing the material after it is broken.Suitable for grinding all kinds of ores and other materials, can be used in mineral processing, building materials industry, but also suitable for chemical industry and other industries.

Ball mill is an important grinding equipment, which is mainly composed of a hollow cylindrical shell rotating around its axis, and the inner part of the cylindrical shell is filled with grinding media, such as steel balls, ceramic balls, etc. As the drum rotates, the material to be ground is sandwiched between the grinding medium and the drum wall, reducing its size by bumping and rubbing against each other. The size of the finished product can be controlled by adjusting the rotation speed and the size of the grinding medium used.

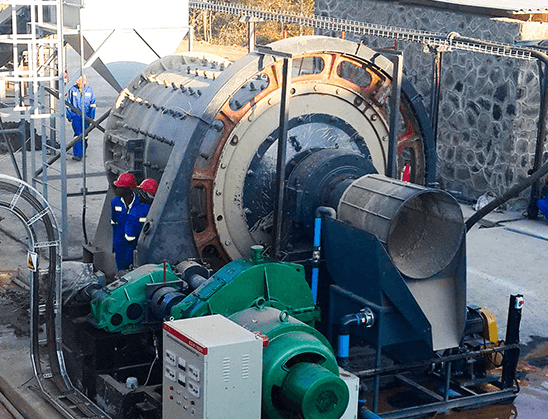

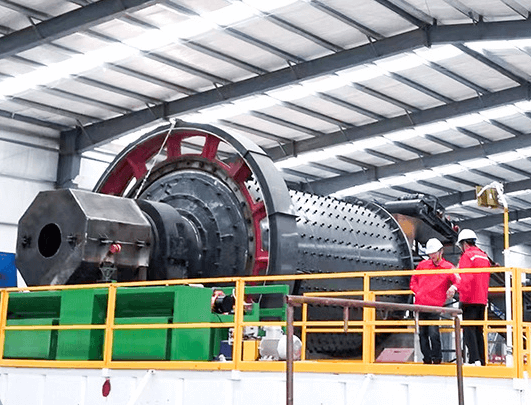

The working principle of the ball mill is to use the abrasive and the grinding ball in the cylinder to grind the raw materials. When the ball mill starts to work, the electromechanical drive cylinder rotates through the transmission device, and at the same time, the feeding device sends the raw materials evenly into the cylinder. The raw material is constantly subjected to the impact, friction and grinding of abrasive and grinding ball in the cylinder, and gradually ground into the required fine powder. The grinding process can be divided into coarse grinding and fine grinding two stages, through the control system, can achieve automatic control, improve production efficiency and product quality.

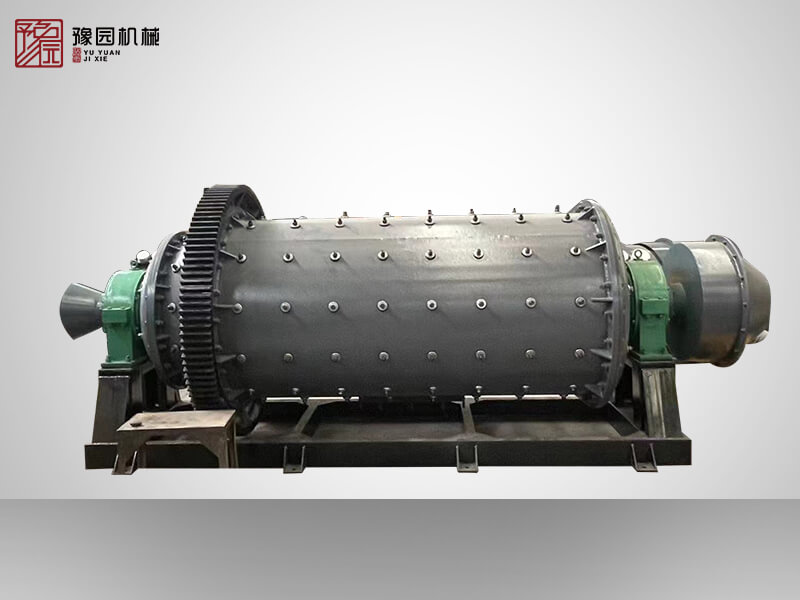

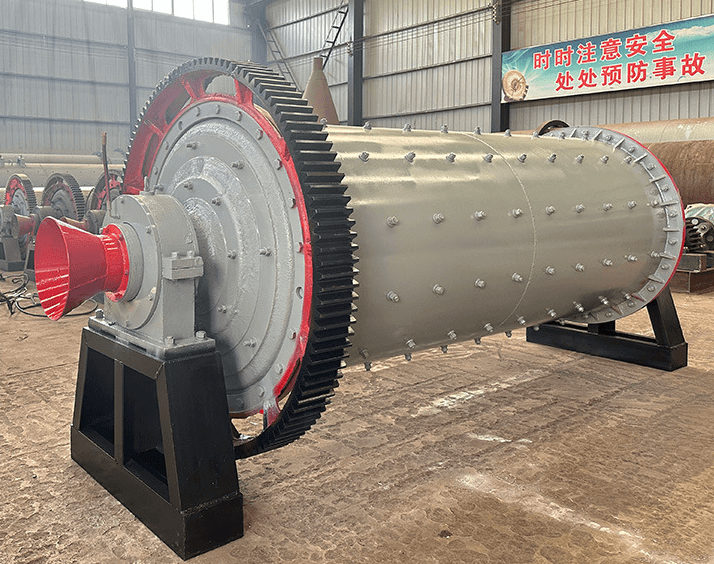

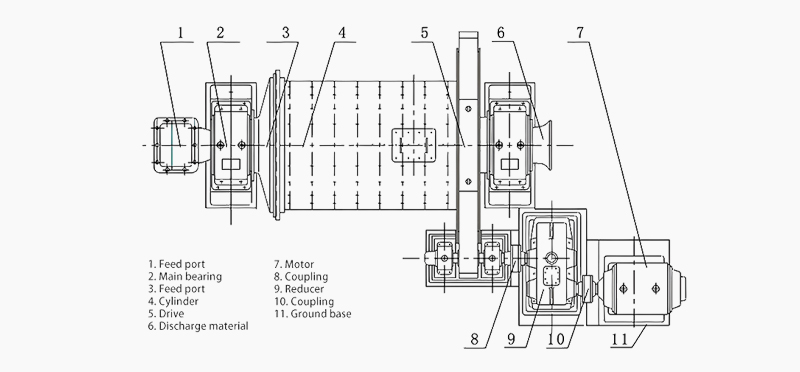

The ball mill is mainly composed of barrel, end cover, main bearing, hollow journal, transmission gear and feeder. The cylinder body is welded by steel plate, and the lining plate is laid inside. The main bearing is a sliding bearing, using thin oil concentrated circulation lubrication. The transmission gear ring is fixed on the cylinder at the discharge end and meshes with the pinion. The motor drives the cylinder through the pinion and the big gear ring.

Ball mills are widely used in many production industries, including but not limited to cement, building materials, refractories, fertilizers, black and non-ferrous metal beneficiation, and glass ceramics. In these industries, ball mills are mainly used for dry or wet grinding of various ores and other grindable materials.

Ball mill is suitable for grinding all kinds of ores and other materials, can be used in mineral processing, building materials industry, but also suitable for chemical industry and other industries. Specific materials include but are not limited to cement clinker, chemical raw materials, ceramic raw materials, metallurgical raw materials and waste, glass raw materials and waste glass.

Material adaptability: can be made into different sizes of the mill to meet the requirements of various production capacity, the output per hour from several hundred grams to two or three hundred tons, especially continuous production, to meet the needs of modern large-scale industrial production.

Crushing ratio: up to more than 300, easy to adjust the fineness of the product, uniform product particle size, mixing effect is also good.

Strong adaptability: It can be operated in different conditions, can be produced by dry method, can also be produced by wet method, and can also be dried and powdered together at the same time.

Simple structure, strong: reliable operation, easy maintenance and management, long-term continuous operation.

Good tightness: there is a good sealing device, can prevent dust flying.

| Specification and model | Cylinder speed (r/min) | Ball load (t) | Feed size (mm) | Discharge size (mm) | Yield (t/h) | Motor power (kw) | Machine weight (t) |

| 900x1800 | 38 | 1.5 | <20 |

0.075-0.89 |

0.65-2 |

18.5 | 3.6 |

| 900x3000 | 38 | 2.7 | <20 |

0.075-0.89 |

1.1-3.5 |

22 | 4.6 |

| 1200x2400 | 32 | 3.8 | <25 |

0.075-0.6 |

1.5-4.8 |

45 | 12.5 |

| 1200x3000 | 32 | 5 | <25 |

0.074-0.4 |

1.6-5 |

45 | 12.8 |

| 1200x4500 | 32 | 7 | <25 | 0.074-0.4 |

1.6-5.8 |

55 | 17 |

| 1500x3000 | 27 | 8 | <25 | 0.074-0.4 |

2-5 |

90 | 21 |

| 1500x4500 | 27 | 14 | <25 | 0.074-0.4 |

3-6 |

110 | 24.7 |

| 1500x5700 | 27 | 15 | <25 | 0.074-0.4 | 3.5-6 | 132 | 28 |

| 1830x3000 | 24 | 11 | <25 | 0.074-0.4 | 4-10 | 180 | 32 |

|

1830x4500 |

25.4 | 15 | <25 | 0.074-0.4 | 4.5-12 | 155 | 34 |

| 1830x6400 | 24 | 23 | <25 | 0.074-0.4 | 6.5-15 | 210 | 42 |

| 1830x7000 | 24 | 25 | <25 | 0.074-0.4 | 7.5-17 | 145 | 50 |