Impact sand making machine is a kind of high efficiency gravel sand making equipment, widely used in metal and non-metal ores, cement, refractory materials, abrasives, glass raw materials, building aggregates, artificial sand making and various metallurgical slag crushing and rough grinding operations.

Impact sand making machine is a kind of high efficiency gravel sand making equipment, which is widely used in metal and non-metal ores, cement, building aggregates and artificial sand making fields. Its core working principle is based on the crushing method of "stone beating stone", that is, the material collids with the material accelerated by the impeller in the process of natural fall, so as to achieve the purpose of crushing. This crushing method not only improves the crushing efficiency, but also reduces the wear of the counter plate of the equipment.

The structure of the impeller and vulnerable parts of the VSI5X impact crusher has been optimized based on mechanical analysis and verification. Compared with traditional impact crushers, its material throughput and crushing ratio have increased by 30%-60% and its cost of wearing parts has been reduced by more than 40%.

In consideration of the maintenance and replacement of parts in the sand making process, we have introduced a semi-automatic hydraulic system. The operator can open the top cover of the machine for maintenance and other operations only by pressing a button, thereby reducing the labor costs and improving the work efficiency.

According to the actual production, we found that the vulnerable parts such as the guard plate and the impact block wear fast. Hence, we design its wearing parts with a split type, which greatly extends their service life and reduces their using cost.

Considering the customers need to switch between the center feeding mode and the cascading feeding mode of the sand making machine according to their production needs, Shibang Group has improved the design of the bulk material tray, so that the operator can easily complete the mode switch, thereby reducing the downtime for adjustment.

Yuyuan Machinery has a high-precision CNC machine tool production line that the steel plate cutting, bending, planing, milling, and painting all have realized manual precision control. Certain core components are accurate to 0.01mm or below.

As an enterprise integrating production and sales, Yuyuan Machinery is responsible for every equipment we produce, providing customers with technical services and original parts supply services throughout the product life cycle to secure the production process of our customers.

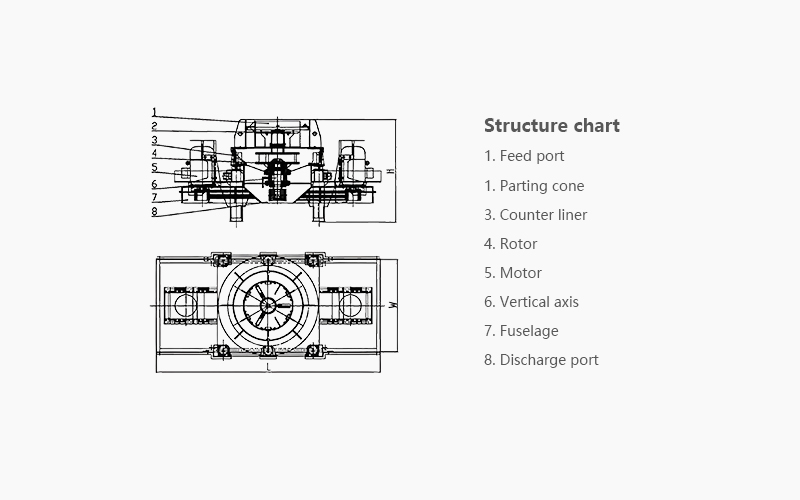

The impact sand making machine is mainly composed of seven parts: feed, distributor, vortex crushing chamber, impeller experience, spindle assembly, base transmission device and motor. Its working principle is based on the principle of stone beating stone, that is, let the stone collide with the stone accelerated by the impeller in the natural falling process, so as to achieve the purpose of crushing. In the crushing process, a vortex is formed when the stone thrown out by acceleration collides with the natural falling stone, and the secondary crushing is carried out during the return process, thus reducing the wear of the machine's counterattack plate.

Impact breakers play an important role in the production of building aggregates, road fabrics, bedding materials, asphalt concrete and cement concrete aggregates

Impact crusher is widely used in metal and non-metallic ores, cement, refractory materials, abrasives, glass raw materials, building aggregates, artificial sand and various metallurgical slag crushing and rough grinding operations. Especially for medium hard, especially hard and abrasive materials such as silicon carbide, emery, sintered aluminum vanadium, magnesia, etc., impact sand making machine has more advantages than other types of crusher

| Model | Soft materials Hard materials | Sand making shaping | Main shaft speed (r/min) | Power (kW) | Dimensions (mm) | ||

| Maximum feed size (mm) | Throughput (t/h) | ||||||

| VSI5X1145 | 50 | 45 | 500-640 | 250-360 | 1100-1310 | 220x2 | 5000x2790x3320 |

| VSI5X9532 | 45 | 40 | 350-540 | 180-280 | 1300-1510 | 160x2 | 4560x2600x2900 |

| VSI5X8522 | 40 | 35 | 240-380 | 120-190 | 1500-1700 | 110x2 | 4140x2500x2700 |

| VSI5X7615 | 35 | 30 | 150-280 | 70-140 | 1700-1900 | 75x2 | 4100x2330x2300 |