It is widely used in intermediate and fine crushing (sand making) of hard and brittle materials such as rocks, abrasives, refractory materials, cement clinker, quartz stone, iron ore, and concrete aggregate. It is especially suitable for sand for building sand and road construction.

Vertical shaft sand making machine is widely used to deal with a variety of hard materials, such as shale, glass, ceramics, bluestone, metal ore crushing processing, has a high crushing capacity. It is mainly used to deal with brittle materials with medium hardness and large water content, and can convert natural materials into sand with required particle size.

Vertical shaft sand making machine is widely used in building materials, mining, chemical industry, metallurgy, cement, coal and other industries. In addition, it plays an important role in the artificial sand making of river pebbles, mountain rocks (such as limestone, granite, basalt, etc.), as well as in the production of construction aggregates, road fabrics, bedding materials, asphalt concrete and cement concrete aggregates. In water conservancy and hydropower, high-grade highways, railways, Bridges, airport runways, municipal engineering and high-rise building stone molding and other engineering projects, vertical shaft sand making machine is also essential.

Vertical shaft sand making machine is suitable for all kinds of stone, construction waste, ore, cement, refractory materials, bauxite clinker and other fields. Especially for shale, glass, ceramics, bluestone, metal ore and other hard materials, the vertical shaft sand making machine has a strong crushing capacity.

the working principle

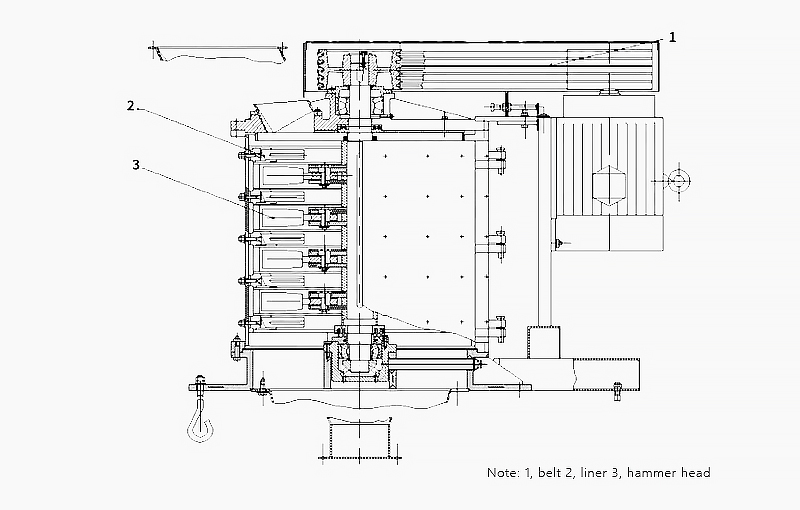

The working principle of vertical shaft sand making machine is mainly based on impact crushing. The motor drives the spindle, which is equipped with a hammer. The material enters the machine from the feed port, is impacted by the high-speed rotation of the hammer head, the material is broken to the required particle size, and is discharged through the discharge port. In the crushing process, the material will experience multiple shocks and displacements, so as to achieve deep crushing.

Structure

Vertical shaft sand making machine is mainly composed of main machine, transmission device, feeding device, screening device, lubrication system and so on. Among them, the main engine is the core component, including rotor, hammer head, counter plate and so on. The transmission device is responsible for transmitting the power of the motor to the main engine to make it rotate. The feeding device is used to feed the material to be crushed into the main machine, and the screening device is responsible for screening the crushed material according to the particle size. The lubrication system ensures lubrication of the main engine and transmission and reduces wear.

(1) Simple and reasonable structure and low operating cost. Less wear by means of crushing stones with stones.

(2) High crushing rate and energy saving.

(3) Fine crushing and coarse grinding.

(4) Less affected by the material's moisture content (8% at most).

(5) Low working noise - below 75 decibels (dB level) and less dust pollution.

(6) Suitable for crushing medium-hard and extra-hard materials.

(7) The product can be shaped into a cube, which is suitable for piling up and has low iron pollution.

(8) The self-lining of the impeller is hardly worn and easy to maintain.

| Model | Feed size (mm) | Discharge size (mm) | Production capacity (t/h) | Motor power (kw) | Dimensions (mm) |

| 800 | <100 | <3-5 | 10-20 | 37 | 2100x1200x1700 |

| 1000 | <100 | <3-5 | 20-40 | 75 | 2600x1400x1900 |

| 1250 | <100 | <3-5 | 40-70 | 110 | 2800x1600x2100 |

| 1500 | <150 | <3-5 | 70-100 | 160 | 3100x1900x2200 |

| 1750 | <150 | <3-5 | 130-160 | 200 | 3710x2360x2390 |

| 2000 | <150 | <3-5 | 180-250 | 250 | 4100x2660x2620 |