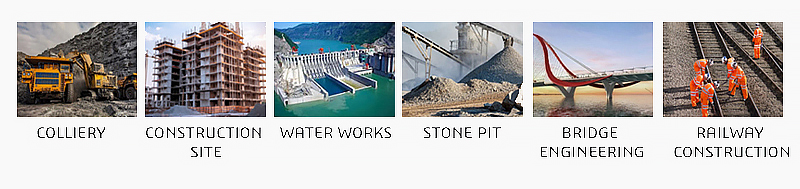

Box type mobile crushing station is a free mobile crusher, which combines innovative technology and sophisticated process design, complete functions, high efficiency and energy saving, stable and reliable, beautiful appearance, long life, easy to operate, and can adapt to various terrain conditions.It is widely used in urban construction, metallurgy, energy, environmental protection, road and bridge construction and other fields.

The introduction of mobile crusher (mobile crushing plant) removes the time-consuming steel frame structure and foundation construction during crushing. The mobile crushing plant can directly select the site and work in the stone mining site, avoiding the pollution and consumption costs brought by raw material transportation. The mobile crusher is not only very suitable for the treatment of construction waste, but also can operate normally under the conditions of small operating sites and harsh operating environment.

The mobile crushing plant is a new type of stone crushing equipment, which greatly expands the concept of crushing operation. It is designed to eliminate the barriers to crushing operations posed by crushing sites and environment and to provide customers with cost effective hardware facilities for project operations.

Different configurations can be adopted according to the characteristics of processing materials, scale and end-product requirements. The main engine includes jaw crusher, impact crusher, cone crusher, vibrating screen, sand making machine, heavy hammer crusher, fine crusher and other equipment. So mobile jaw crushers, mobile medium and fine crushing plants (impact crushers/cone crushers), mobile sand making plants and mobile screening plants are available for different purposes.

The mobile crushing plant adopts a modular assembly form, which integrates all stand-alone equipment on one frame, including feeders, crushers, vibrating screens, conveyor belts, chassis, racks, generator sets, etc.. Alternatively, the process of crushing first and then screening or screening first and then crushing, or a two-stage crushing and screening system of coarse crushing and fine crushing, or a three-stage crushing and screening system of coarse crushing, medium crushing and fine crushing can be formed according to different crushing process requirements. The highly integrated equipment is quicker to start production and easier to switch between sites, without the need of foundation construction.

The installation form of integrated unit equipment eliminates the complicated site infrastructure installation work of split components, and reduces the consumption of materials and labor hours. The reasonable and compact space layout of the unit improves the flexibility of stationing at sites and is more conducive to moving into reasonable construction areas.

The mobile crushing plant has a high chassis, a body width less than that of the operating semi-trailer, and a small turning radius, which is convenient for driving in rugged and harsh road environment in crushing sites besides on ordinary roads, and can provide a reasonable layout for the overall crushing process.

The mobile crushing plant can crush materials on site, avoiding the intermediate link of transporting materials away from the site and crushing again, which greatly reduces the transport costs. In addition, the extended unit can directly send the crushed materials into the box hopper and transport them away from the site.

The mobile crushing plant can be used independently, and more flexible process configuration can also be provided according to the customer's requirements for material type and products in the process, so as to meet the various requirements of users such as mobile crushing and screening, and make the generation of materials and transportation more direct and effective.

As for the applicable materials, the mobile crusher can handle a variety of types of materials, including soft or medium hard and hard materials, such as oil shale, fluorite, briquetcoal, light calcium carbonate, chromite, kaolin, lead zinc ore, activated carbon, talc, silicon carbide, chromium oxide green, potassium ore, fluorite, phosphorus boron ore, pyrolusite, tungsten ore, skarn, coke, calcium magnesium sulfate, medical stone, potassium feldspar and so on.

Crusher can handle a wide range of materials, including large ores, stones, rocks and other materials. In the quarry, it is often used to break stone, limestone, granite, marble and other ores; In metallurgy, construction, cement and other industries, it is used to break materials with higher hardness, such as coal ash, limestone, iron ore and so on. In addition, it can also be used to break some special materials, such as cellulose panels, concrete blocks of old buildings, steel waste and so on.