Jaw crusher, also known as tiger mouth, is an important mining machinery and equipment. It is composed of two jaw plates, the moving jaw and the static jaw, which simulate the two jaw movements of animals to complete the material crushing operation.

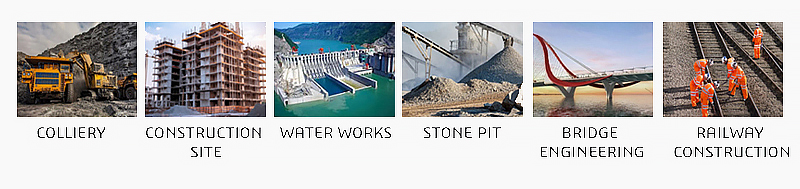

Jaw crusher has the characteristics of large crushing ratio, uniform product particle size, simple structure, reliable work, easy maintenance, economic operating costs and so on. This crusher in mining, smelting, building materials, roads, railways, water conservancy and chemical industry and many other sectors have a wide range of applications, can crush compressive strength of not more than 320 mpa of various materials.

The jaw crusher breaks the material through the periodic movement of the moving jaw. In the process of swinging around the axial fixed jaw of the suspension center, the material is located between the two jaw plates and is subjected to the combined action of crushing, splitting and bending. At the beginning, the pressure is small, the material volume is reduced, and the materials are close to each other and squeezed tightly; When the pressure rises to exceed the strength that the material can withstand, the material will be broken. Each periodic movement of the moving jaw causes the material to be crushed once and sent down some distance. After a number of cycles, the broken material is discharged from the discharge port.

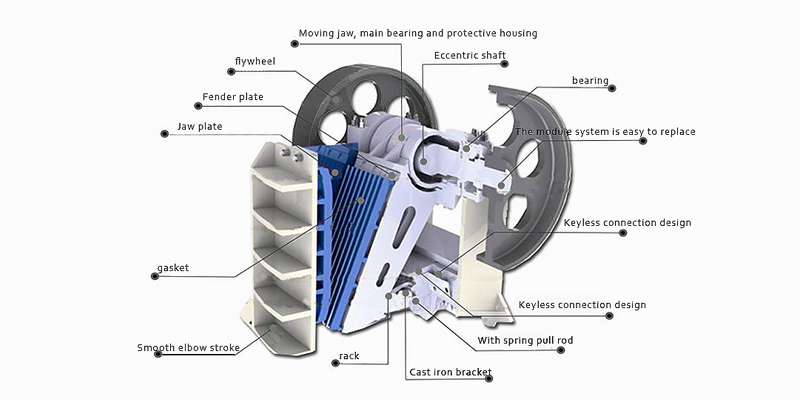

Crusher is mainly composed of frame, eccentric shaft, large belt pulley, flywheel, side protection plate, elbow plate, elbow plate backseat, adjusting screw, reset spring, fixed jaw plate and movable jaw plate. In addition, it also includes a regulating device, a lubricating device, a rotating body and a adjusting device and other components.

Jaw crusher is widely used in mining, smelting, building materials, road, railway, water conservancy and chemical industry and many other sectors. Specifically, it has important applications in quarry, metallurgy, construction, cement, chemical and other industries.

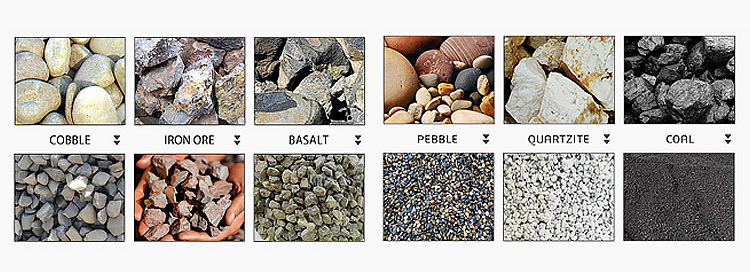

Crusher can handle a wide range of materials, including large ores, stones, rocks and other materials. In the quarry, it is often used to break stone, limestone, granite, marble and other ores; In metallurgy, construction, cement and other industries, it is used to break materials with higher hardness, such as coal ash, limestone, iron ore and so on. In addition, it can also be used to break some special materials, such as cellulose panels, concrete blocks of old buildings, steel waste and so on.

| Model number | Feed size (mm) | Maximum feed size (mm) | Discharge port adjustment range (mm) | Processing capacity (t/h) | Eccentric shaft speed (r/min) | Motor power (kW) | Dimensions (L × W × H) (mm) |

| PE150x250 | 150x250 | 125 | 10-40 | 1-3 | 268 | 4P 5.5 | 760x700x860 |

| PE200x300 | 200x300 | 180 | 15-50 | 2-6 | 260 | 4P 7.5 | 915x780x990 |

| PE200x350 | 200x350 | 180 | 18-60 | 3-10 | 276 | 4P 11 | 1000x914x1112 |

| PE250x400 | 250x400 | 210 | 20-70 | 5-21 | 300 | 6P 15 | 1100x1032x1285 |

| PE400x600 | 400x600 | 340 | 40-100 | 16-64 | 270 | 6P 30 | 1623x1736x1615 |

| PE500x750 | 500x750 | 425 | 50-100 | 40-110 | 268 | 6P 55 | 1920x1850x1920 |

| PE600x750 | 600x750 | 500 | 150-200 | 80-240 | 268 | 6P 55 | 2020x1850x1920 |

| PE600x900 | 600x900 | 500 | 65-160 | 50-160 | 254 | 6P 55 | 2530x1900x2340 |

| PE750x1060 | 750x1060 | 630 | 80-180 | 110-320 | 245 | 8P 110 | 2680x2380x2785 |

|

PE900x1200 |

900x1200 | 750 | 100-200 | 220-380 | 208 | 8P 110 | 3470x2876x3330 |

| PE1200x1500 | 1200x1500 | 1020 | 150-350 | 400-1000 | 180 | 8P 160-240 | 4850x3220x3680 |

| PE1500x180 | 1500x1800 | 1200 | 220-350 | 500-1200 | 180 | 8P 280-380 | 5160x3660x4248 |

| PEX150x750 | 150x750 | 120 | 18-48 | 8-25 | 320 | 4P 15 | 1170x1575x103 |

| PEX250x750 | 250x750 | 210 | 25-60 | 13-35 | 320 | 6P 22 | 1550x1730x1470 |

| PEX250x1000 | 250x1000 | 210 | 25-60 | 16-52 | 330 | 6P 30 | 1580x2006x1390 |

| PEX250x1200 | 250x1200 | 210 | 25-60 | 20-61 | 330 | 6P 37 | 1780x2214x1430 |

| PEX300x1300 | 300x1300 | 250 | 20-90 | 16-105 | 300 | 6P 55 | 2210x2320x1723 |