Compound crusher is a kind of equipment for medium and fine crushing, widely used in mining, construction, water conservancy, electric power, railway, highway, chemical, building materials and other industries.

Compound crusher is a kind of multi-functional crushing equipment, its design combined with advanced crushing technology, so that it performs well in a variety of material crushing operations. The machine has the dual functions of crushing and grinding, which can realize the crushing of various hardness materials, and the crushing ratio is large and the output is high.

1. Simple and reasonable structure, low operating cost, large crushing ratio, high output, but the operating cost is lower than similar equipment.

2. It has the function of fine crushing and coarse grinding, high crushing rate and remarkable energy-saving effect.

3. Small impact on material moisture content, water content up to about 8%, low noise, less dust pollution.

4. The broken product has good shape, high packing density and little iron pollution

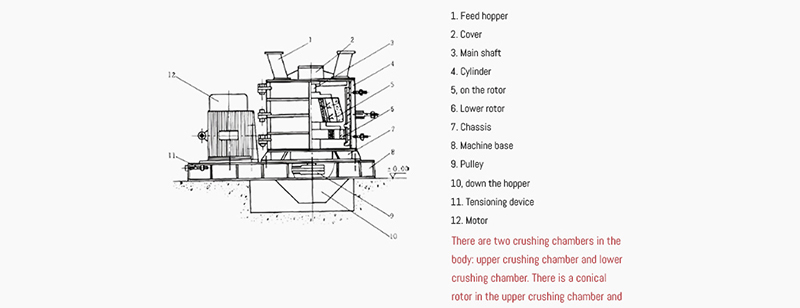

The compound crusher uses an elastic adjusting mechanism, which can be automatically discharged when it encounters unbreakable materials, thus avoiding damage to the equipment. The broken particles are discharged from the discharge port through the discharge device, which can be adjusted as needed to control the size and distribution of the particles. In addition, the crusher also includes the crushing chamber, crushing tools, transmission and control system and other parts to achieve the crushing and refining of raw materials.

Compound crusher is a kind of equipment for medium and fine crushing, widely used in mining, construction, water conservancy, electric power, railway, highway, chemical, building materials and other industries.

Compound crusher is mainly used for crushing materials above medium hardness, such as iron ore, limestone, granite, etc., but also suitable for some specific materials such as cement plant raw materials, clinker crushing operations, as well as dolomite, coke gems, lead zinc ore, serpentine, blast furnace slag, coal gangue, phosphate rock and other medium hardness materials crushing operations. In addition, the compound crusher is especially suitable for hard limestone, dolomite, granite, basalt and other artificial sand or highway pavement stone processing and crushing.

| Specification | Processing capacity (t/h) | Motor power (kw) |

| 800 | 5-15 | 4P 30 |

| 1000 | 10-30 | 4P 55 |

| 1250 | 17-60 | 6P 132 |

| 1500 | 25-80 | 8P 160 |

| 1750 | 30-100 | 8P 200 |