The fine crusher is an effective, practical and reliable crushing machine at present. It combines external equipment technology and research and development according to the detailed working conditions of cement industry, mining, mineral processing and recycled concrete manufacturers to develop sand making machines for medium Mohs hardness materials.

Fine crusher is also known as new fine crusher. This machine has a wide range of uses, and its performance has reached a high level. It is an effective, practical and reliable crusher, especially suitable for the fine and secondary crushing hard and brittle materials such as abrasive, refractory, cement, quartz sand, and steel sand. It features energy-saving and environmental-friendly performance, which saves 50% more energy than the traditional fine crusher.

1. It is the third-generation PXJ sand-making machine (high-efficiency fine crusher), features excellent operating performance, simplified process, simple, reasonable and compact structure, and is easy to replace parts and maintain.

2. It changes the three-level crushing to secondary crushing, which has a large production capacity and long hammer service life and is environmentally friendly and energy-saving.

3. It boosts the high chromium blow bar, counter liner hard rock crushing, inertia impact balancing device, and easily disassembled maintenance window. The size of the discharged particles can be adjusted, simplifying the crushing and sand-making process.

4. Compared with the traditional sand-making machine of the same scale, its yield is increased by 30%~50% (the one-time rate of a finished product of ≤5mm can reach 85% above).

5. Compared with the traditional sand-making machine of the same scale, it can save 50%~70% of electricity (it can be driven by only one motor).

6. Its finished sand materials are shaped into cubes with strong compressive capacity, which can meet high-standard construction needs (few needle or flake materials).

7. Compared with the traditional sand-making machine of the same scale, its maintenance cost is reduced by 50%~60%. (The vulnerable parts can be purchased locally)

8. Together with the jaw crusher, it directly forms a sand-making line, which saves the impact crusher and sand-making machine, thereby reducing the investment.

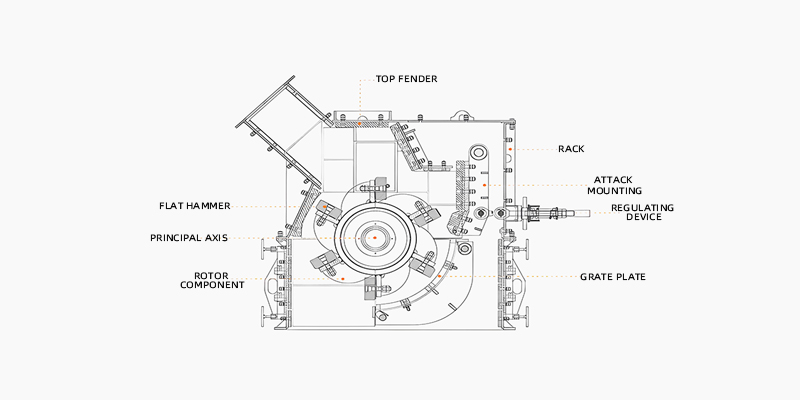

When the third-generation PXJ sand-making machine (high-efficiency fine crusher) starts, the materials enter the chamber and fall on the high-speed rotating movable hammer. Under the action between the hammer and the impact plate, the materials are initially crushed in the hammer area. After being repeatedly hammered and counterattacked, the materials fall on the center spacer, pile up and then fall on the throwing tray of the lower rotor rotating at high speed. Then they are thrown to the counterattack plate at high speed to collide and fall. At last, the materials are impacted, crushed, and ground by the mobile blow bar. Therefore, the materials undergo multiple crushing, scouring, and grinding during falling. Thus it completes the process of fine crushing.

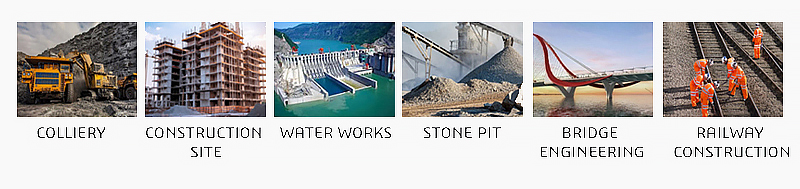

The crusher is widely used in various fields, including mechanical sand and stone aggregate, high-grade highway, railway, water conservancy, airport, construction, cement, refractory, metallurgy and so on. In these industries, the fine crusher plays an important role in the production of sand aggregate.

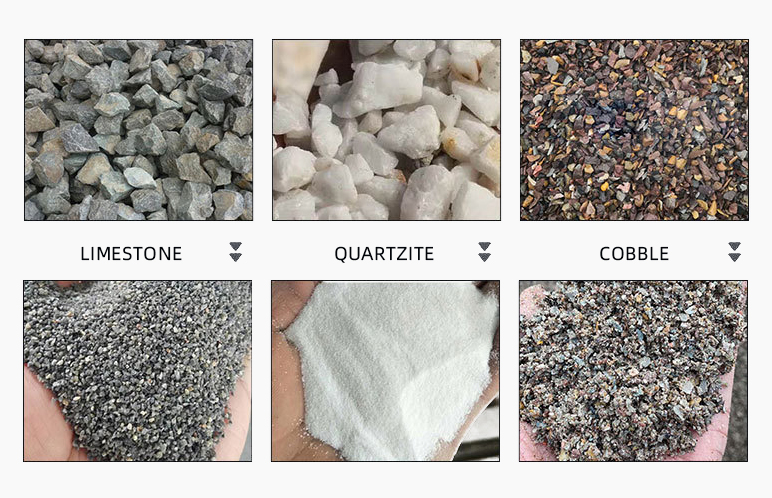

It is especially suitable for the fine and medium crushing of abrasive, refractory, cement, quartz sand, steel sand, slag powder, copper ore, iron ore, gold ore, concrete aggregate, asphalt aggregate and other hard and brittle materials. For silicon carbide, carborundum, sintered bauxite, sand and other high hardness, extra hard and abrasion resistant materials

| PXJ fine crusher | Rotor ø x width (mm) | Rotor ø x width (mm) | Rotor ø x width (mm) | Rotor ø x width (mm) | Rotor ø x width (mm) | Rotor ø x width (mm) | Rotor ø x width (mm) | Rotor ø x width (mm) |

| Model | 400x800 | 600x800 | 800x800 | 1010x1010 | 1200x1200 | 1400x1400 | 1600x1600 | 1800x1800 |

| Feed size (mm) | 400x185 | 500x250 | 550x330 | 1000x350 | 1200x450 | 1500x500 | 1600x550 | 1800x800 |

| Feed size (mm) | <120 | <180 | <180 | <180 | <180 | <190 | <190 | <190 |

| Discharge size (mm) | 5-10 | 5-10 | 5-10 | 5-10 | 5-10 | 5-10 | 5-10 | 5-10 |

| Discharge gap adjustment width (mm) | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 |

| Cement clinker (t/ h) | 10-30 | 18-40 | 20-45 | 25-55 | 50-110 | 50-150 | 85-210 | 125-270 |

| Limestone (t/h) | 18-45 | 23-55 | 28-65 | 35-75 | 45-100 | 50-150 | 95-260 | 140-310 |

| Power (kw) | 37 | 37 | 45 | 55 | 110 | 160 | 250 | 315 |

| Theoretical weight (t) | 3.9 | 4.5 | 6 | 10.5 | 14.4 | 22 | 35 | 49.7 |