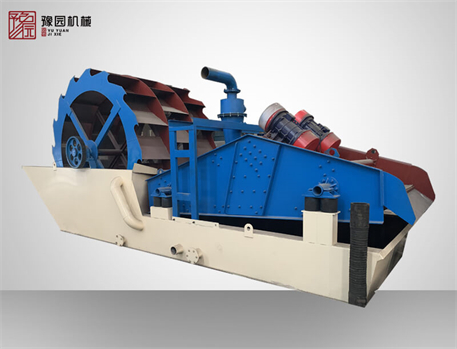

The fine sand recovery machine is a kind of equipment developed for dehydration, desliming and desliming of slurry materials, aiming at solving the problem of fine sand loss in sand making industry.

The fine sand recovery machine is a kind of equipment developed for dehydration, desliming and desliming of slurry materials, aiming at solving the problem of fine sand loss in sand making industry. It is also known as tail sand recovery machine, fine sand extraction machine, fine sand collection machine, sediment separator, mud separator, sand water mixture treatment system.

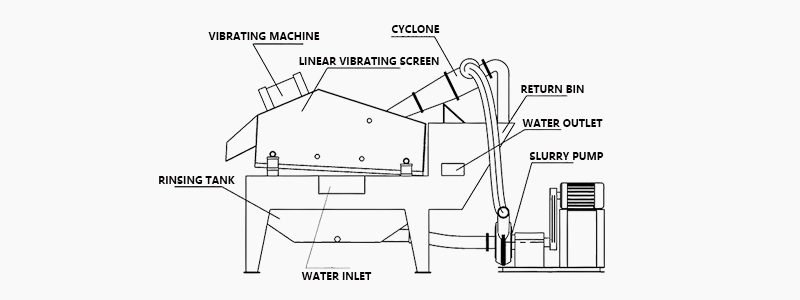

The feed tailings are evenly fed into the feed port of the sieve by the feed box (or swirler), and about 1/3 of the water is removed at the place where the pre-dehydration sieve plate is installed at 45 degrees from the horizontal plane. After the feed tailings enter the joint of the flat screen plate and the inclined screen plate, the accumulation of materials occurs, and the material particles settle by gravity to form a thinner filter layer, which prevents the remaining particles from passing through the sieve, making the filter layer gradually thicker.

The water that cannot pass through the sieve forms a pool on the upper part of the filter layer. Since the filter layer here is thin, the water gradually comes off under strong movement. The vibration state of high frequency and low amplitude makes the tailings and other particles that form the filter layer more and more dense and vibrates them to the discharge port, and the materials form a filter cake shape. Part of the moisture in the material is removed from the screen surface, and the rest is attached to the surface of the material layer due to capillary action. Due to the negative incidence of the screen surface, water will not overflow from the discharge port, but flow to the joint pool, so as to complete the material dewatering work.

1. High working frequency, high vibration intensity, low moisture in the product on the screen, and high unit processing capacity.

2. The power source is a vibrating motor, without bearings, couplings and other vulnerable parts. With a simple structure and low maintenance costs, it is easy to install and repair, and can work continuously for 24 hours.

3. The screen surface of the pre-dewatering sieve plate is installed at 45 degrees to the horizontal plane, and the sieve plate is installed at negative incidence to increase the dehydration area and promote the dehydration of the material as soon as possible to form a filter layer.

4. The side plate and the beam, the motor base and the reinforcement plate are all connected by torsional shear type high-strength bolts, without welds, which avoids the cracking of the side plate caused by welding stress.

5. The sieve plate is made of imported polyurethane material, with high porosity, good water permeability and long service life.

6. The small sieve machine adopts rubber springs for vibration reduction, with low noise and good vibration reduction effect, which can greatly reduce the dynamic load of the sieve machine on the foundation. The large sieve machine uses high manganese steel springs, which have good elasticity and long service life.

7. The whole machine adopts finite element structure analysis software to ensure that the strength, stiffness and stress of the screen frame are reasonable, and it is light in weight and low in energy consumption.

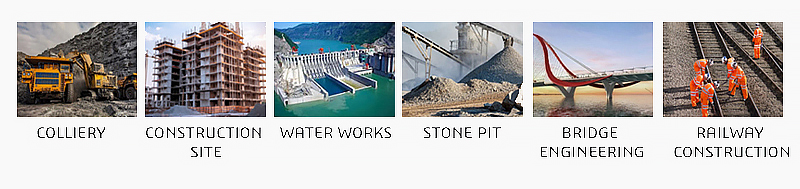

In the application industry, the fine sand recovery machine has a wide range of applications. In the construction industry, it can be used in concrete mixing stations, mortar production lines and other places, recycling waste fine sand, reduce production costs, improve resource utilization. In the mining industry, it can be used for wastewater treatment during ore processing to reduce environmental pollution. In the metallurgical industry, it can be used in the wastewater treatment of metal smelting process to recover valuable metal resources. In addition, it is also widely used in hydropower station sand aggregate processing system, glass raw material processing system, artificial sand production line, coal preparation plant crude coal slime recovery and environmental protection engineering (mud purification) and other fields.

In terms of applicable materials, the fine sand recovery machine can recover fine sand from a variety of materials, including but not limited to limestone, granite, river pebbles, iron ore, basalt, etc.

| Model number | Sand pump Power (kw) | Water treatment (m³/h) |

| 250 | 11 | 30-6- |

| 300 | 15 | 60-100 |

| 350 | 18.5 | 70-130 |

| 550 | 11×2 | 100-220 |

| 650 | 15×2 | 120-272 |

| 750 | 18.5×2 | 180-350 |

| 900 | 18.5×3 | 450-650 |