A circular vibrating screen is a new type of vibrating screen with circular motion, multiple layers and high efficiency. It adjusts the amplitude with the cylinder-type eccentric shaft vibrator and the eccentric block.

A circular vibrating screen is a new type of vibrating screen with circular motion, multiple layers and high efficiency. It adjusts the amplitude with the cylinder-type eccentric shaft vibrator and the eccentric block. It has a long screen flow line and is applicable to various screening specifications, and it is featured by reliable structure, strong vibration force, high screening efficiency, low vibration noise, durability, easy maintenance, and safe, which is widely used in mining, building materials, transportation, energy, chemical and other industries.

1. Few wearing parts. It has few wearing parts except the screen, so it boasts a low failure rate in operation and a long service life for the whole machine.

2. Simple structure, reasonable design, easy operation, and quick removal and replacement of the screen surface, which effectively reduces downtime.

3. Reasonable motor configuration. It screens one ton of material with less electric energy and stronger power, which obviously improves the yield.

4. Strong vibration of the screen box. It can prevent materials from blocking the screen hole, contributing to high screening efficiency and productivity.

The circular vibrating screen runs in a circular or elliptical. It uses an inertial vibration exciter to generate vibration, and the vibration source is generally driven by a motor. The circular vibrating screen is a single-shaft vibrator. The main shaft on the screen box rotates at a high speed driven by the motor, and the eccentric body installed on the main shaft rotates accordingly. The centrifugal inertia force makes the free-vibrating screen box vibrate in an approximate circular track.

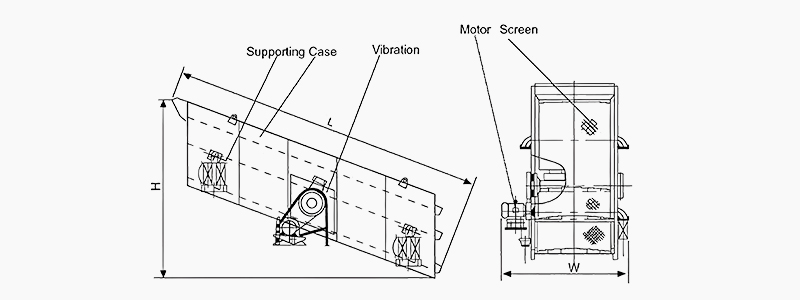

The circular vibrating screen is mainly composed of a screen box, screen, vibrator, damping spring device, chassis, suspension (or support) device and motor. It is a multi-layer circular vibrating screen.

In the application industry, the vibrating screen sand machine is widely used in mixing station, road and bridge engineering, construction site, sand mining site, coal yard, grain depot and other industries. Its screening and separation ability is helpful to save manpower and financial resources, improve project quality, accelerate project progress and increase economic benefits. At the same time, it is also suitable for the processing of brittle and ductile materials in refractories, cement, metallurgy, chemical industry, electric power, coal and other industries, as well as crushing and fine crushing of various medium-hardness ores and rocks in mineral processing, building materials and other industrial sectors.

In the applicable materials, the vibrating sand screen machine is not only suitable for mixed materials, but also for mechanical sand (such as river pebbles, limestone, quartz stone, etc.) and natural sand (such as river sand, river sand, sea sand, etc.) for effective screening.

| Model number | Number of screen layers | Screen area (㎡) | Screen size (mm) | Maximum feed size (mm) | Processing capacity (t/h) | Vibration frequency (r/min) | Double amplitude (mm) | Motor power (kw) | Weight (t) |

| 2YK1235 | 2 | 4.2 | 5-50 | 400 | 15-100 | 800-970 | 8 | 5.5 | 3.2 |

| 3YK1235 | 3 | 4.2 | 5-50 | 400 | 30-100 | 800-970 | 8 | 7.5 | 4.4 |

| 2YK1545 | 2 | 6.75 | 5-50 | 400 | 50-180 | 800-970 | 8 | 15 | 5.3 |

| 3YK1545 | 3 | 6.75 | 5-50 | 400 | 50-210 | 800-970 | 8 | 15 | 6.1 |

| 4YK1545 | 4 | 6.75 | 5-50 | 400 | 50-240 | 800-970 | 8 | 18.5 | 6.9 |

| YK1848 | 1 | 8.8 | 5-10 | 400 | 56-330 | 755 | 11 | 15 | 7.2 |

| 2YK1848 | 2 | 8.8 | 5-100 | 400 | 56-330 | 750 | 11 | 15 | 6.2 |

| 3YK1848 | 3 | 8.8 | 5-100 | 400 | 56-330 | 970 | 7 | 22 | 7 |

| 2YK1860 | 2 | 10.8 | 5-80 | 400 | 56-330 | 800--970 | 8 | 22 | 8 |

| 3YK1860 | 3 | 10.8 | 5-80 | 400 | 50-360 | 800--970 | 8 | 22 | 8.6 |

| 4YK1860 | 4 | 10.8 | 5-80 | 400 | 100-400 | 800--970 | 8 | 30 | 9.2 |

| 2YK2160 | 2 | 12.6 | 5-100 | 400 | 100-430 | 970 | 8 | 30 | 8.8 |

| 3YK2160 | 3 | 12.6 | 5-100 | 400 | 100-460 | 970 | 8 | 30 | 9.45 |

| 4YK2160 | 4 | 12.6 | 5-100 | 400 | 120-460 | 970 | 8 | 45 | 10.9 |

| 2YK2460 | 2 | 14.4 | 5-100 | 400 | 150-500 | 970 | 8 | 37 | 9.63 |

| 3YK2460 | 3 | 14.4 | 5-100 | 400 | 150-550 | 970 | 8 | 45 | 11.5 |

| 4YK2460 | 4 | 14.4 | 5-100 | 400 | 180-600 | 970 | 8 | 55 | 12.78 |