Wheel bucket sand washing machine is a wheel bucket type washing equipment, which is mainly used for cleaning and separating stone powder soil in sand and stone, and is a sand washing equipment used in conjunction with sand making machine.

The wheel bucket sand washing machine uses the powerful force generated by the rotation of the wheel bucket to clean the sand and stone. The sand washing machine adopts a novel sealing structure and a reliable transmission device to ensure the cleaning and dehydration effect. In addition, it has simple structure, almost no wearing parts, long service life and easy maintenance.

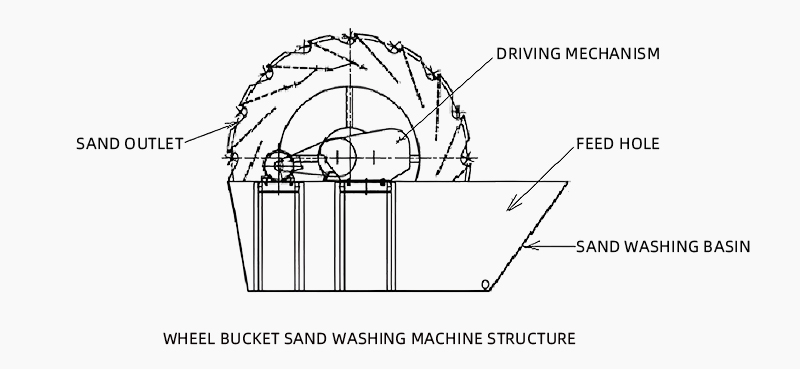

The working principle of the wheel bucket sand washing machine is: the motor drives the impeller to slowly rotate after being decelerated by the triangle belt, the reducer and the gear. The sand and stone enter the washing tank from the feeding tank, roll and grind each other under the drive of the impeller to remove the impurities covering the surface of the sand and stone, and destroy the water vapor layer covering the sand and facilitate dehydration. At the same time, water is added to form a strong water flow, and impurities and foreign bodies with small specific gravity are taken away in time, and discharged from the overflow outlet washing tank to complete the cleaning effect. The clean sand is carried away by the blades and then poured into the discharge chute from the rotating impeller.

1. Durable: The wheel bucket sand washing machine adopts advanced cleaning technology, which can remove impurities on the surface of the material well and improve the quality and utilization rate of the material. Its novel sealing structure and fully enclosed transmission ensure efficient and durable performance.

2. Environmental protection and energy saving: The equipment adopts a closed circuit water circulation system, which can recycle water resources and reduce water consumption. At the same time, it can also filter out impurities in the material and reduce pollution to the environment.

3. Easy operation: The wheel bucket sand washing machine is simple to operate, can achieve automatic control, reduce manual intervention, reduce the difficulty of operation and work intensity.

4.Easy maintenance: its structure is simple, easy to maintain, reduce maintenance costs and workload.

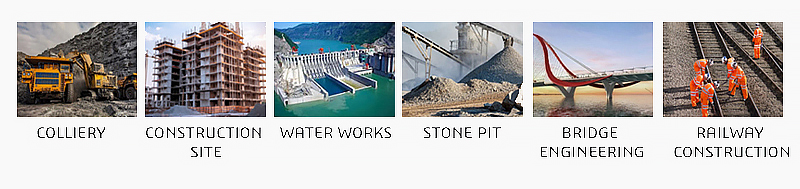

Wheel bucket sand washing machine is widely used in sand and gravel fields, mines, water conservancy and hydropower, concrete mixing station and other industries. It is especially suitable for washing, grading and impurity removal in metallurgy, building materials, hydropower and other industries, and is especially suitable for construction sand and road sand.

Wheel bucket sand washing machine is suitable for a variety of materials, including stone powder, river pebbles, pebbles, limestone, granite, quartz sand, machine sand, river sand and so on. It can effectively remove the impurities on the surface of these materials and improve the cleanliness and quality of the materials.

| Model number | 2000 | 2600 | 2800 | 3000 | 3200 | 3600 | 4500 |

| Bucket diameter (mm) | 2000 | 2600 | 2800 | 3000 | 3200 | 3600 | 4500 |

| Speed (r/min) | 3 | 2.5 | 1.8 | 1.7 | 1.44 | 1.21 | 1 |

| Maximum feeding size (mm) | ≤5 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

| Processing capacity (t/h) | 4-6 | 30-60 | 50-70 | 70-100 | 80-120 | 120-180 | 180-250 |

| Motor power (kw) | 3 | 5.5 | 5.5 | 7.5 | 11 | 15 | 22 |

| Overall dimensions (mm) | 2800×2000×2200 | 3200×2270×2672 | 3700×2500×2990 | 3900×2700×2990 | 3965×3100×3300 | 4355×3400×3700 | 5155×3750×4600 |

| Weight (t) | 2.5 | 2.9 | 4 | 5.2 | 6.6 | 8.8 | 12.8 |