Spiral sand washing machine is a kind of equipment widely used in highway, water and electricity, construction and other industries for washing, grading, and impurity removal, especially suitable for the washing operation of fine and coarse-grained materials.

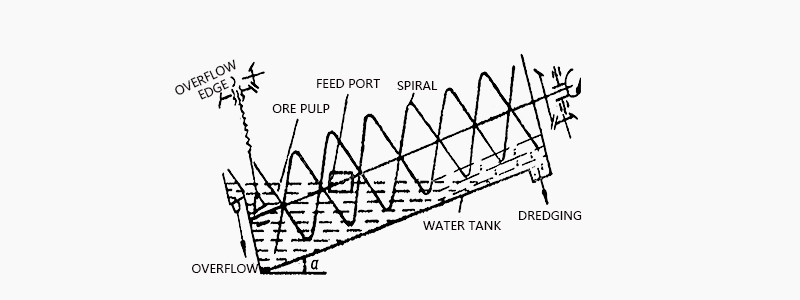

The spiral sand washing machine is divided into two types: single spiral and double spiral. The main function is to stir the sand and stone through the spiral device in the equipment, so that the soil and water in the sand and stone are mixed, and then discharged from the flow port on the equipment. At the same time, the sand and stone are gradually screened under the action of the spiral device and discharged from the top discharge port to achieve the cleaning and screening effect of the sand and stone.

The structure of the spiral sand washing machine mainly includes spiral blades, intermediate shafts, sinks and motors. The spiral blade is installed on the intermediate shaft and is continuously rotated by the motor driven by the reducer. The lower part of the tank is surrounded by three weir plates to form a sedimentation tank, and the spiral head is sunk into the sedimentation tank. When working, the cleaning water is fed into the porous plate at the bottom of the sedimentation tank, and the sand and stone are fully mixed with the water under the drive of the spiral blade and are gradually screened.

High efficiency and durability:Spiral sand washing machine has the characteristics of small power consumption, high cleaning degree, good sealing structure, fully enclosed transmission device, etc., to ensure high efficiency and durability of the product.

Multiple effects:The equipment has three functions of cleaning, dehydration and classification, which can effectively separate impurities such as soil and ash powder on the material to obtain clean materials.

Large processing capacity:high single output, up to 180 tons/hour, to meet the needs of large-scale sand washing.

Cost saving:less investment in the machine, low power, less power consumption, effectively saving production costs.

Strong cleaning ability:The spiral sand washing machine can effectively clean the sand and stone with serious mud impurities, and ensure the quality of the sand and stone.

Spiral sand washing machine is not only suitable for metallurgy, building materials, hydropower and other industries, but also plays an important role in construction sites, gravel plants, prefabrication plants and hydroelectric power stations and other places, for sand removal and screening operations.

Spiral sand washing machine can handle a variety of materials, including but not limited to cement, quartz sand, steel sand, slag powder, copper ore, iron ore, gold ore, concrete aggregate, asphalt aggregate, etc. It can effectively deal with materials in the range of 0~30mm, separating dirt and dust on the material into clean materials.

| Specifications | 2200 | 2600 | 2900 | 3500 |

| Bucket diameter (mm) | 2200 | 2600 | 2900 | 3500 |

| Speed (r/min) | 1-2 | 1-2 | 0.8-1.5 | 0.8-1.2 |

| Processing capacity (t/h) | 15-30 | 20-50 | 50-100 | 120-200 |

| Motor power (kw) | 4 | 5.5 | 7.5 | 11 |

| Total weight (kg) | 4300 | 5600 | 8100 | 9900 |

| Overall dimensions (L×W×H)(mm) | 3150×1910×2280 | 3520×2390×2690 | 3820×2640×3200 | 4420×2930×3800 |