Shaftless drum screen adopts shaftless design and is a kind of screening equipment. It is mainly used for the classification of ribbon and strong winding materials, such as construction waste, domestic waste, etc., but also widely used in the classification of refractory materials, coal, fertilizer, sand and stone, as well as coal, coke, white ash, sand gold and other wet materials screening.

Shaftless drum screen adopts shaftless design and is a kind of screening equipment. It is mainly used for the classification of ribbon and strong winding materials, such as construction waste, domestic waste, etc., but also widely used in the classification of refractory materials, coal, fertilizer, sand and stone, as well as coal, coke, white ash, sand gold and other wet materials screening.

High yield: The shaftless design makes the yield about 20% higher than the traditional shafted drum screen.

Anti-blocking: through the rotation and tumbling of the drum, the material can be turned over several times on the screen, and the material stuck in the screen can be popped out, effectively preventing the screen from blocking.

Easy maintenance: The internal roller screen accessories are individually designed, making the screening space larger, while simplifying the maintenance process.

Simple structure: shaftless roller screen structure is simple, making it run smoothly, friction coefficient is small, wear is small, extend the service life of the equipment.

High screening efficiency: The use of special screen, making the screening efficiency is higher, the effect is better.

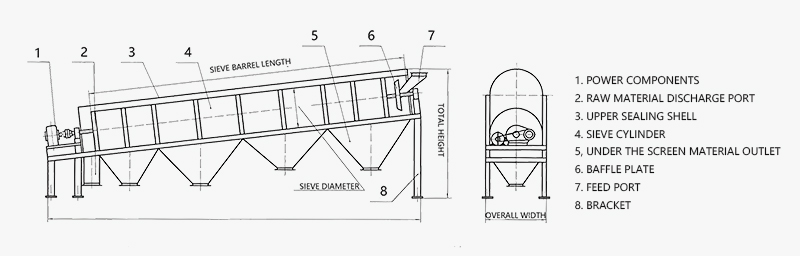

Shaftless drum screen is mainly composed of screen box, driving device, supporting device, transmission device and sealing device. The screen box is the core part of the entire equipment, which is composed of a number of different sizes of screens for screening and screening of materials. The driving device is used to drive the rotation of the screen box, while the support device is responsible for supporting the entire device. The transmission device connects the drive device to the screen box and transfers power to the screen box to make it rotate. Seals are used to prevent material leakage during screening.

The working principle of shaftless drum screen is mainly to rotate the screen box through the driving device, so that the material is screened and screened on the screen. When the material enters the screen box, due to the different aperture size of the screen, the large particle material can not pass through the small aperture screen, while the small particle material can pass through the large aperture screen. After the material is screened several times on the screen, different specifications of particulate matter are obtained.

Shaftless drum screen is a screening equipment developed for power station, coking plant, metallurgy, chemical industry, mining, building materials, domestic waste, scrap waste, decoration waste, construction waste treatment and other industries. Its wide applicability allows it to play a key role in a number of industries to solve sticky screening and clogging problems during the screening of wet and viscous materials, improving the performance and reliability of the screening system.

Shaftless roller screen is suitable for screening mud, metal, sand, wood chips, solid waste of various properties and wet and easily blocked materials. Its shaftless design makes it particularly suitable for handling materials that are prone to entanglement or clogging, resulting in improved screening efficiency.

| Model number | 1230 | 1530 | 1830 | 2030 |

| Yield (m³/h) | 20-50 | 40-80 | 80-150 | 130-200 |

| Outer screen diameter (m) | 1.2 | 1.5 | 1.8 | 2 |

| Length (m) | 3 | 5 | 6 | 8 |

| Power (kw) | 3 | 5.5 | 7.5 | 11 |

| Overall dimensions (mm) | 3580×1590×1675 | 3980×1790×1975 | 4150×1870×2240 | 4230×1950×2950 |