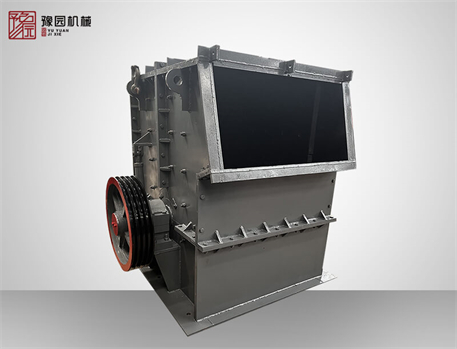

Box crusher, also known as heavy hammer crusher or square box crusher, is a synthesis of a variety of crushing machinery principles, optimized design after the manufacture of a new generation of crushing machinery products.

The box-type crusher, featuring a single heavy hammer with a significant moment of inertia and a high-speed rotor, boosts its strength of crushing small and light by being big and heavy and its unique performance in crushing super-large stones.

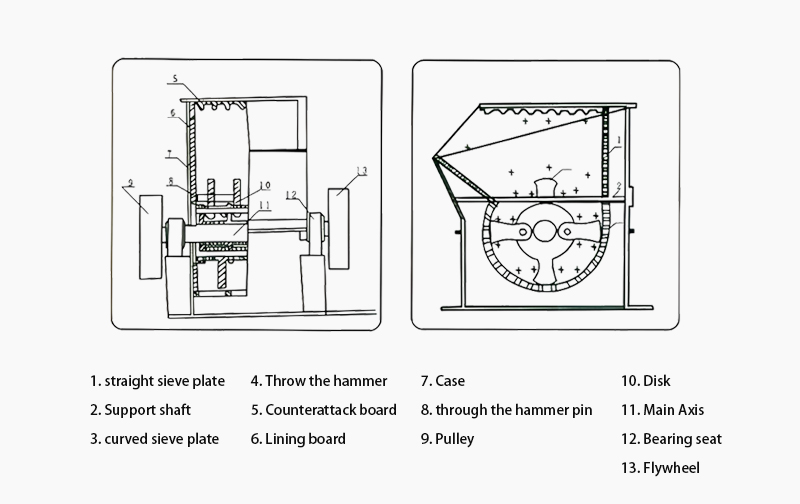

The stones fall directly from the machine's upper part into the turntable rotating at high speed. Under the action of high-speed centrifugal force, the stones are crushed at high speed and density. With the mutual effect, the stones form a vortex motion between the turntable and the casing for further hitting, rubbing, and crushing till the stones are crushed into the particle size as required.

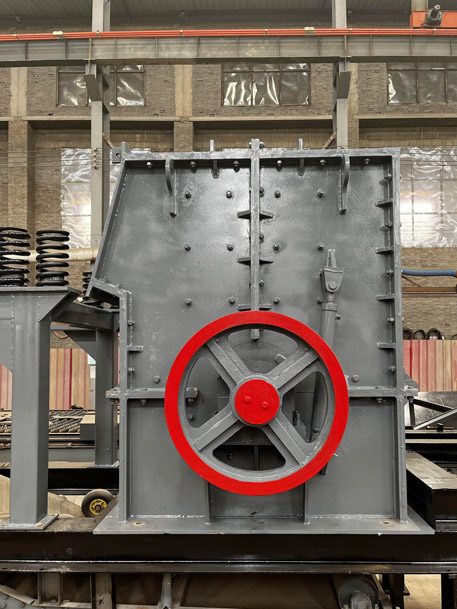

The frame of a box-type crusher comprises three parts. You can carry out inspection and maintenance operations such as replacing the blow bar, crushing plate and lining plate by opening the rear casing. The components of the box-type crusher are of high compatibility, and most of them are wear-resistant parts, which are good for the procurement and management of spare parts. Its casing opens and closes with a hydraulic opening device, which effectively reduces labor intensity, improves work efficiency and shortens the work time of maintenance. The monitoring system of the crusher can monitor its operating status at any time. The monitoring signal can be sent to the main control system so that it can ensure the safe and reliable operation of the machine. The drive system of the box-type crusher, composed of the motor, mechanical coupling, V-belt, and crusher, effectively improves the starting performance of the motor and enables the motor to start and run smoothly. Belt transmission gives double overload protection. The drive system requires low motor power, which greatly reduces the operating cost. This driving method is greatly cost-effective and of excellent practicability, excellent performance, safety and reliability.

1. Large feed size, high crushing ratio, and uniform output.

2. High finished product rate, 85% being granular products, which fully meet the requirements for use.

3. Adjustable hammer shaft of the box-type crusher and long service life of the hammer.

4. Adjustable grid size, controllable product particle size, and good particle shape.

5. Reversible casing of the box-type crusher, convenient for inspection and maintenance.

6. Square shank bolts, resistant to impact and abrasion.

7. High output and stable performance.

8. Coarse and medium crushing in one step, easy and simple process flow

9. Hammer, grate plate and counter-attack plate made of high wear-resistant materials with longer service life.

10. Small power, low energy consumption, simple maintenance, and few wearing parts.

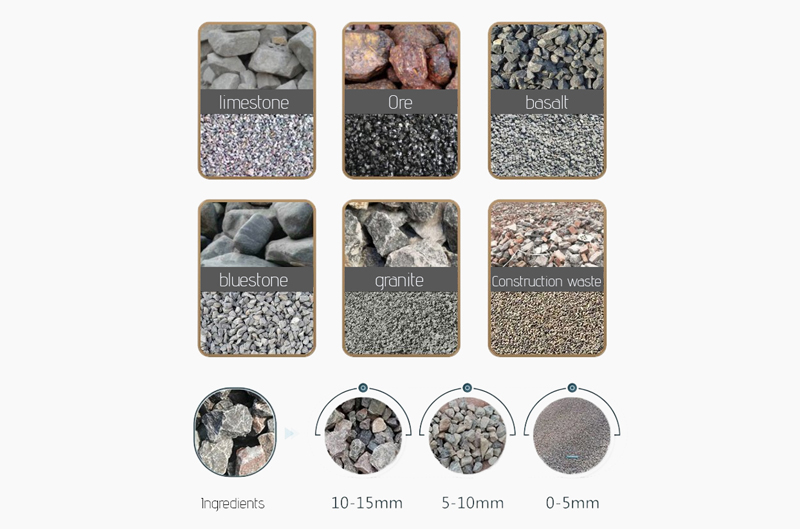

box crusher is especially suitable for crushing materials in mining, building materials, chemical industry, metallurgy and other industries. In these industries, the box crusher can handle a variety of materials well to meet production needs.

The crushing materials of the equipment are very wide, including coal, salt, chalk, gypsum, brick, limestone and so on. In addition, it can also be used to break fiber structures, scrap wood, paper or scrap asbestos cement with strong elasticity and toughness to recover asbestos fibers.

| Model | Rotor diameter (mm) | Rotor length (mm) | Output (t/h) | Feed size (mm) | For stone | Power (KW) |

| 700x1000 | 700 | 1000 | 50-80 | ≤500 | Stones with pressure of 300MPa | 45-55 |

| 900x1200 | 900 | 1200 | 70-100 | ≤800 | 75-90 | |

| 1000x1000 | 1000 | 1000 | 90-120 | ≤800 | 75-90 | |

| 1200x1200 | 1200 | 1200 | 130-160 | ≤900 | 110-132 | |

| 1400x1400 | 1400 | 1400 | 190-210 | ≤1000 | 132-160 | |

| 1600x1600 | 1600 | 1600 | 250-300 | <1000 | 160-210 | |

| 1800x1800 | 1800 | 1800 | 300-400 | <1200 | 210-280 |