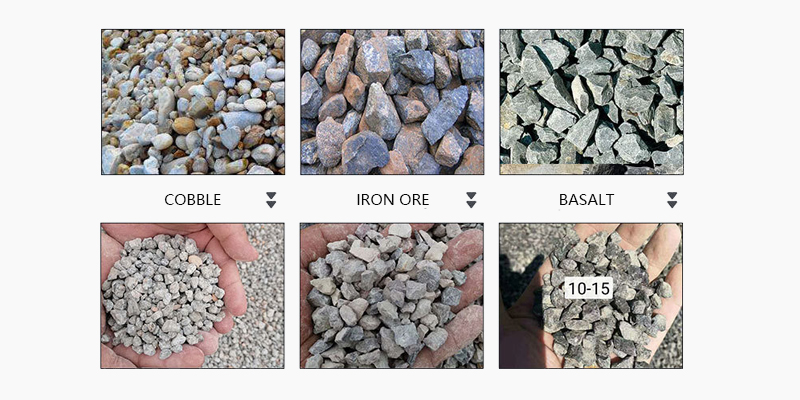

The multi-cylinder hydraulic cone crusher applies to ores and rocks with medium hardness and above, such as limestone, iron ore, pebbles, non-ferrous metal ores, granite, basalt, limestone, quartzite and sandstone.

The multi-cylinder hydraulic cone crusher applies to ores and rocks with medium hardness and above, such as limestone, iron ore, pebbles, non-ferrous metal ores, granite, basalt, limestone, quartzite and sandstone. The crushed products are in good cubic shape thanks to the high speed and crushing capacity. Also, it is easy to maintain and runs stably. Multi-cylinder cone crusher is one of the cone crushers commonly used by customers. Its price is relatively affordable, and its yield range is extensive, which can meet the production requirements.

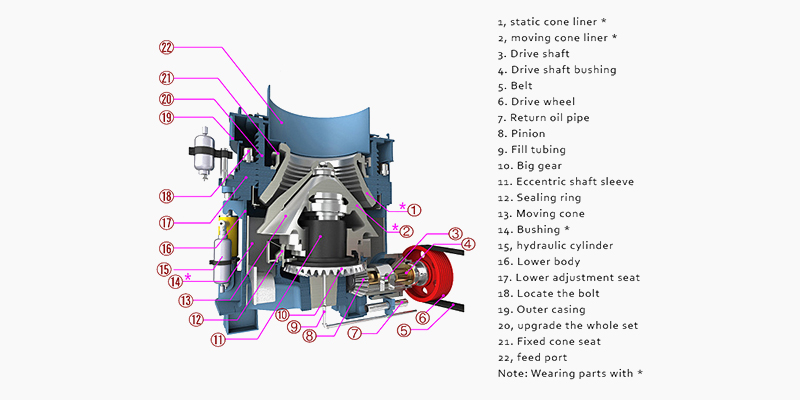

When it starts, the motor drives the pulley or coupling, the transmission shaft and the cone to make the eccentric shaft make a periodic swinging motion under the axis line. After the materials enter the crushing chamber from the feed opening, they are crushed under the mutual squeeze, grind and rub forces by the eccentric shaft and the breaking cap wall. The hydraulic insurance system can remove the obstructions from the support sleeve and the fixed cone through hydraulic pressure in case of an iron fault or too much load, which secures the machine, greatly reduces the maintenance rate, and improves production efficiency.

The HPM multi-cylinder cone crusher is mainly composed of a fixed cone, movable cone eccentric bushing, transmission, rack, adjustment ring, feeding bin, discharge opening, locking protection, oil cylinder, fan, and motor hydraulic pressure.

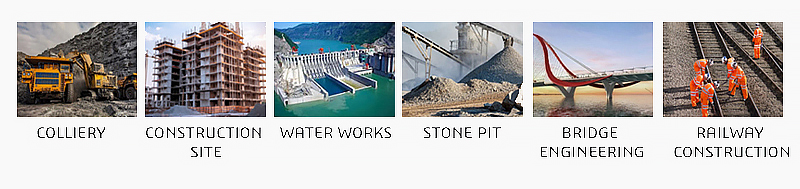

Cone crusher is widely used in metallurgy, construction, road construction, chemistry, silicate and other industries, as well as mining, smelting, building materials, highway, railway, water conservancy and chemical industry and many other sectors.

Cone crusher is suitable for crushing materials of various hardness, including iron ore, limestone, copper ore, quartz, granite, sandstone and so on. The different crushing principle and the different particle size of the product also determine that it is suitable for the treatment of different materials.

1. Large crushing ratio, high efficiency: cone crusher adopts innovative crushing technology, combining higher speed and stroke, so that the rated power and passing capacity of the crusher are greatly improved, thus improving the crushing ratio and production efficiency.

2. Uniform product particle size: Due to the extrusion crushing effect of the conical crushing chamber, the particle size of the crushed material is uniform, which meets the needs of various industries.

3. Low operating cost: The cone crusher has a complete lubrication system, which automatically closes when the temperature is too high or the flow rate is too slow, reducing the downtime and reducing the operating cost.

4. Easy to adjust, economical to use: cone crusher is designed with a safety device, and its thin oil lubrication system design is unique, improve the service life of the equipment, reduce maintenance costs.

5. Wide range of application: cone crusher is suitable for crushing ore and rock above medium hardness, widely used in various industries, including mining, construction, road construction, chemical and silicate.

| Specification | Model | Large end diameter of crushing cone(mm) | Maximum feed size (mm) | Discharge opening width (mm) | Processing capacity (t/h) | Motor power (kw) | Total weight (t) | Dimensions (L x W x H) (mm) |

| Φ600 | PYB600 | 600 | 65 | 12-25 | 40 | 8P 30 | 5 | 2234x1370x1675 |

| PYD600 | 35 | 3-13 | 12-23 | 5.5 | 2234x1370x1675 | |||

| Φ900 | PYB900 | 900 | 115 | 15-50 | 50-90 | 8P 55 | 11.2 | 2692x1640x2350 |

| PYZ900 | 60 | 5-20 | 20-65 | 11.2 | 2692x1640x2350 | |||

| PYD900 | 50 | 3-13 | 15-50 | 11.3 | 2692x1640x2350 | |||

| Φ1200 | PYB1200 | 1200 | 145 | 20-50 | 110-168 | 8P 110 | 24.7 | 2790x1878x2844 |

| PYZ1200 | 100 | 8-25 | 42-135 | 25 | 2790x1878x2844 | |||

| PYD1200 | 50 | 3-15 | 18-105 | 25.3 | 2790x1878x2844 | |||

| Φ1750 | PYB1750 | 1750 | 215 | 25-50 | 180-360 | 8P 160 | 50.3 | 3910x2894x3809 |

| PYZ1750 | 185 | 10-30 | 80-210 | 50.3 | 3910x2894x3809 | |||

| PYD1750 | 85 | 5-13 | 60-180 | 50.2 | 3910x2894x3809 | |||

| Φ2200 | PYB2200 | 2200 | 300 | 30-60 | 420-700 | 8P 280-260 | 80 | 4622x3302x4470 |

| PYZ2200 | 230 | 10-30 | 130-410 | 80 | 4622x3302x4470 | |||

| PYD2200 | 100 | 5-15 | 80-200 | 81.4 | 4622x3302x4470 |