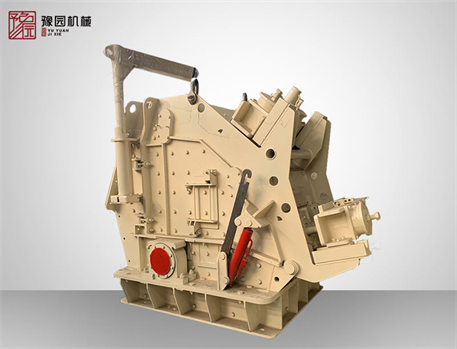

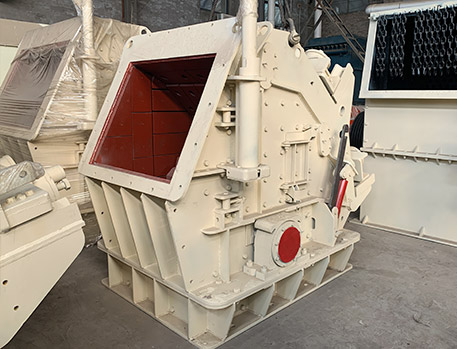

LF large-diameter impact crusher is one of the impact crushers. Its main difference from ordinary impact crushers is the feeding opening. Its opening can crush bigger ores, so it has high crushing efficiency, a big feeding size, and an excellent crushed particle shape.

LF large-diameter impact crusher is one of the impact crushers. Its main difference from ordinary impact crushers is the feeding opening. Its opening can crush bigger ores, so it has high crushing efficiency, a big feeding size, and an excellent crushed particle shape. Materials crushed by the "Stone-to-Iron" principle are finer and smoother than those crushed by the coarse crushing principle by jaw crushing. The size of its discharge particles can be adjusted to meet different crushing specifications. It is widely used for the secondary and fine crushing of materials in industries such as building materials, ore crushing, transportation, energy, and chemical industry.

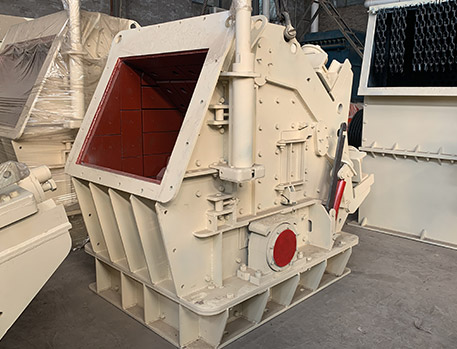

High crushing efficiency: Innovative design of large feed port and high crushing chamber, so that it can handle a variety of materials, large crushing ratio, high crushing efficiency.

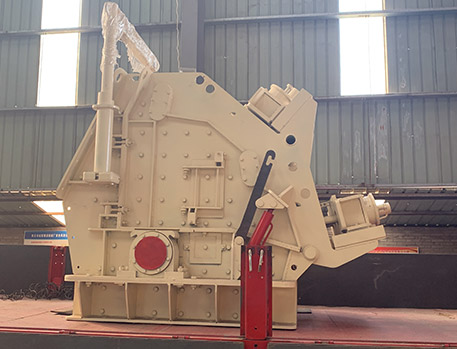

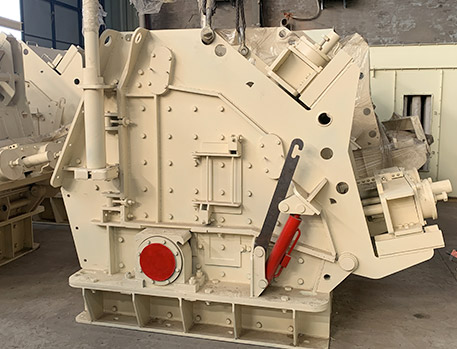

Low investment cost: its structure is simple, small size, light weight, large production capacity, keyless connection, easy maintenance, thus reducing the investment cost.

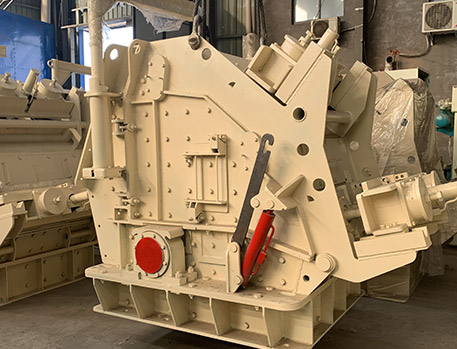

Strong adaptability: the grid size is adjustable, the product particle size is controllable, the particle shape is good, and various configuration forms can be adopted according to the type, scale and finished material requirements of the processing raw materials.

Good durability: The use of high chromium plate hammer, good wear resistance, hammer shaft installation can be adjusted, hammer head long life.

Easy maintenance: The chassis can be turned over, making the maintenance work more convenient.

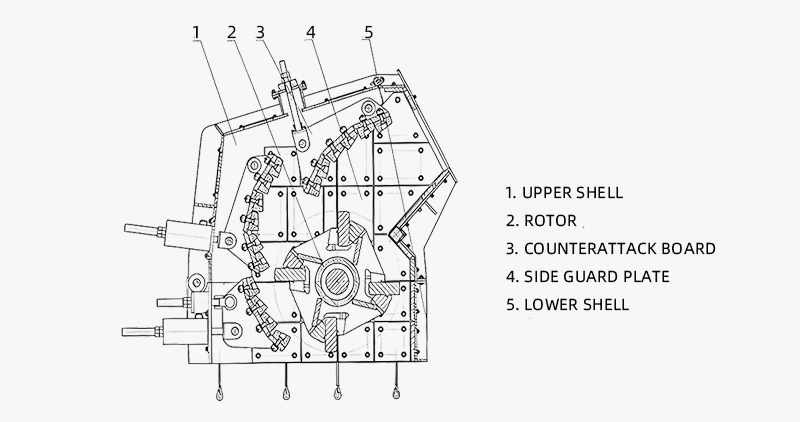

The main working part of the impact crusher is a high-speed rotating rotor with a plate hammer. When working, the material first enters the feed port of the crusher, and then is impacted by the high-speed rotating plate hammer, the material is broken and thrown to the counter plate, and is impacted again, so repeatedly, the material is gradually broken under the impact, rebound, collision and other effects, and then discharged from the lower part of the body.

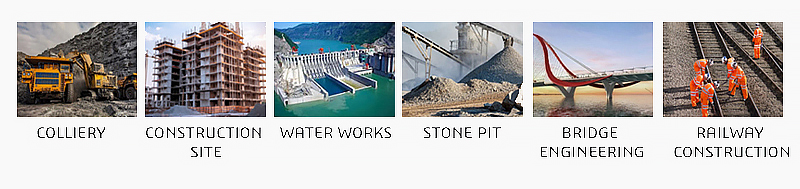

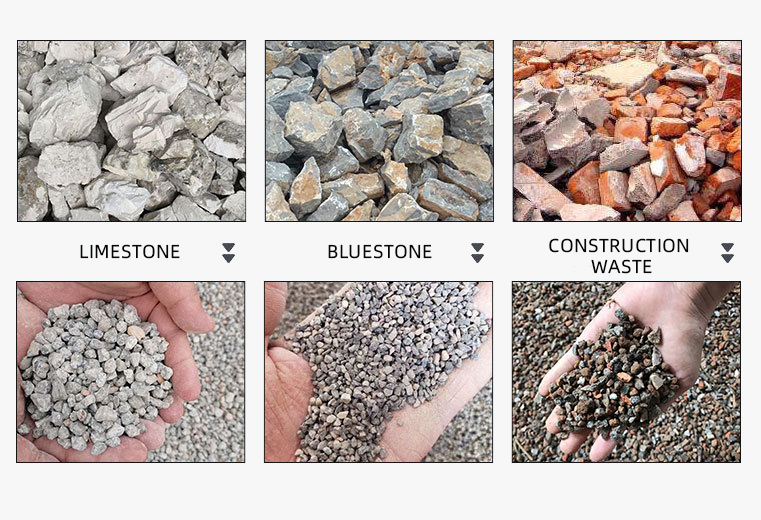

Impact crusher is mainly used in metallurgy, chemical industry, building materials, hydropower and other industries, especially highways, railways, hydropower projects and other need to flow stone operation scenes. At the same time, with the acceleration of the urbanization process, it is also widely used in the treatment of construction waste in urban demolition, helping the recycling of construction waste.

Impact crusher is suitable for all kinds of soft, medium and hard ore crushing and fine crushing materials, including limestone, feldspar, calcite, talc, barite, fluorite, rare earth, kaolin, coke, coal gangue, gypsum and so on. In addition, because of its large feed port and high crushing chamber, it is especially suitable for processing materials with high hardness and large lumpiness, and the product is less stone powder

| Model | Feed size(mm) | Maximum feed size(mm) | Processing capacity(t/h) | Power(kw) | Weight(kg) |

| LF150 | 820X980 | 100-200 | 100-200 | 90-200 | 12000 |

| LF250 | 960X1360 | 200-400 | 200-400 | 180-250 | 17000 |

| LF350 | 1050X1700 | 300-500 | 300-500 | 200-400 | 24000 |