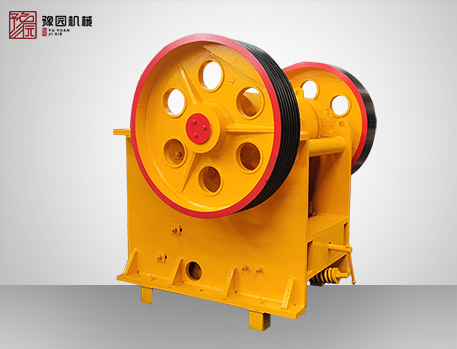

Coarse jaw crusher is a relatively early emergence of crushing equipment, because of its simple structure, strong, reliable work, easy maintenance and production and construction costs are relatively small, so it is still widely used in metallurgy, chemical industry, building materials, electricity, transportation and other industrial sectors.

Coarse crushing jaw crusher is the earliest crushing equipment, because of its simple structure, strong, reliable work, easy maintenance and maintenance and production and construction costs are relatively small, so it is still widely used in metallurgy, chemical industry, building materials, electricity, transportation and other industrial sectors. In recent years, in order to meet the needs of crushing high-strength, high-hardness micro-carbon ferrochrome and other materials, there has also been an Hubei crusher.

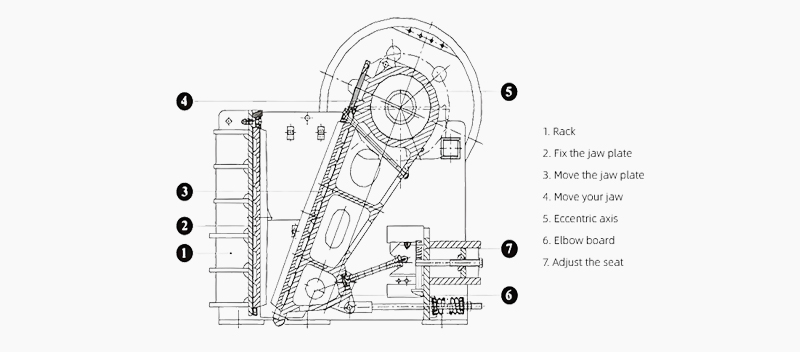

The working principle of the coarse jaw crusher is to simulate the two jaw movements of animals. The working part is two jaw plates, one is a fixed jaw plate (fixed jaw), and the other is an active jaw plate (moving jaw). When working, the motor drives the belt and pulley, and makes the moving jaw move up and down through the eccentric shaft. When the moving jaw rises, the Angle between the elbow plate and the moving jaw becomes larger, thus pushing the moving jaw plate to the fixed jaw plate, and the material can be crushed multiple times through extrusion, rubbing and grinding between the two jaw plates. When the moving jaw goes down, the Angle between the elbow plate and the moving jaw becomes smaller, the moving jaw plate leaves the fixed jaw plate under the action of the pull rod and the spring, and the broken material is discharged freely through the discharge port at the lower part of the jaw cavity under the action of gravity. With the continuous rotation of the motor, the movable jaw is periodically crushed and discharged to achieve mass production.

The structure of the coarse crushing jaw crusher is mainly composed of frame, eccentric shaft, large belt pulley, flywheel, moving jaw, side protection plate, elbow plate, elbow plate backseat, adjusting screw, reset spring, fixed jaw plate and movable jaw plate. The elbow plate also plays an insurance role.

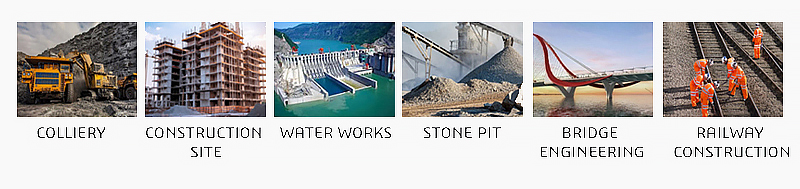

Coarse crushing jaw crusher is mainly used in mining, smelting, building materials, road, railway, water conservancy and chemical industry.

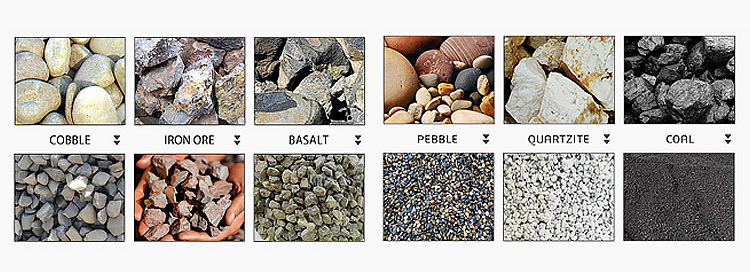

In these industries, it is mainly used for crushing various ores and rocks with compressive strength of 147 ~ 320MPa, such as granite, quartz stone, river pebbles, calcite, concrete, dolomite, iron ore, silicon ore, basalt and so on.

1. Simple structure, easy maintenance and use: the coarse crushing jaw crusher structure is relatively simple, mainly composed of fixed jaw plate and movable jaw plate, easy to operate and maintain.

2. Stable performance, low operating costs: Because of its simple and rugged structure, reliable work, low operating costs.

3. The crushing ratio is large, the product particle size is uniform: the crushing chamber of the coarse crushing jaw crusher is deep and there is no dead zone, which improves the feeding capacity and output. At the same time, its crushing ratio is large and the product particle size is uniform.

4. Gasket type discharge port adjustment device: the device is reliable and convenient, the adjustment range is large, and the flexibility of the equipment is increased.

5. The lubrication system is safe and reliable: the parts are easy to replace and the equipment is simple to maintain.

6. Equipment energy saving: 15% to 30% energy saving for a single machine, more than double the system energy saving.

7. Large adjustment range of discharge port: it can meet the requirements of different users.

8. Low noise, less dust: conducive to environmental protection and safe production.

| Model number | Feed size (mm) | Maximum feed size (mm) | Discharge port adjustment range (mm) | Processing capacity (t/h) | Eccentric shaft speed (r/min) | Motor power (kW) | Dimensions (L × W × H) (mm) |

| PE150x250 | 150x250 | 125 | 10-40 | 1-3 | 268 | 4P 5.5 | 760x700x860 |

| PE200x300 | 200x300 | 180 | 15-50 | 2-6 | 260 | 4P 7.5 | 915x780x990 |

| PE200x350 | 200x350 | 180 | 18-60 | 3-10 | 276 | 4P 11 | 1000x914x1112 |

| PE250x400 | 250x400 | 210 | 20-70 | 5-21 | 300 | 6P 15 | 1100x1032x1285 |

| PE400x600 | 400x600 | 340 | 40-100 | 16-64 | 270 | 6P 30 | 1623x1736x1615 |

| PE500x750 | 500x750 | 425 | 50-100 | 40-110 | 268 | 6P 55 | 1920x1850x1920 |

| PE600x750 | 600x750 | 500 | 150-200 | 80-240 | 268 | 6P 55 | 2020x1850x1920 |

| PE600x900 | 600x900 | 500 | 65-160 | 50-160 | 254 | 6P 55 | 2530x1900x2340 |

| PE750x1060 | 750x1060 | 630 | 80-180 | 110-320 | 245 | 8P 110 | 2680x2380x2785 |

|

PE900x1200 |

900x1200 | 750 | 100-200 | 220-380 | 208 | 8P 110 | 3470x2876x3330 |

| PE1200x1500 | 1200x1500 | 1020 | 150-350 | 400-1000 | 180 | 8P 160-240 | 4850x3220x3680 |

| PE1500x180 | 1500x1800 | 1200 | 220-350 | 500-1200 | 180 | 8P 280-380 | 5160x3660x4248 |

| PEX150x750 | 150x750 | 120 | 18-48 | 8-25 | 320 | 4P 15 | 1170x1575x103 |

| PEX250x750 | 250x750 | 210 | 25-60 | 13-35 | 320 | 6P 22 | 1550x1730x1470 |

| PEX250x1000 | 250x1000 | 210 | 25-60 | 16-52 | 330 | 6P 30 | 1580x2006x1390 |

| PEX250x1200 | 250x1200 | 210 | 25-60 | 20-61 | 330 | 6P 37 | 1780x2214x1430 |

| PEX300x1300 | 300x1300 | 250 | 20-90 | 16-105 | 300 | 6P 55 | 2210x2320x1723 |