Steel plate welding jaw crusher, also known as jaw crusher, is an indispensable crushing equipment in crushing, sand making, grinding and mineral processing production lines. It is mainly used for coarse and medium crushing of various ores and large materials, and in recent years, a compound pendulum jaw crusher for fine crushing has also appeared. This kind of crusher is widely used in many industries because of its advantages of good crushing effect, stable operation and easy maintenance.

Steel plate welding jaw crusher, also known as jaw crusher, is an indispensable crushing equipment in crushing, sand making, grinding and mineral processing production lines. It is mainly used for coarse and medium crushing of various ores and large materials, and in recent years, a compound pendulum jaw crusher for fine crushing has also appeared. This kind of crusher is widely used in many industries because of its advantages of good crushing effect, stable operation and easy maintenance.

The working principle of steel plate welding jaw crusher is mainly through the interaction between the moving jaw and the fixed jaw to achieve the crushing of materials. When the motor drives the belt and pulley, the eccentric shaft makes the moving jaw reciprocate. When the moving jaw is close to the fixed jaw, the material is compressed and bent. When the moving jaw leaves the fixed jaw, the material is stretched and torn. This periodic movement makes the material subject to multiple crushing in the crushing chamber, and then realizes the crushing and discharge of the material.

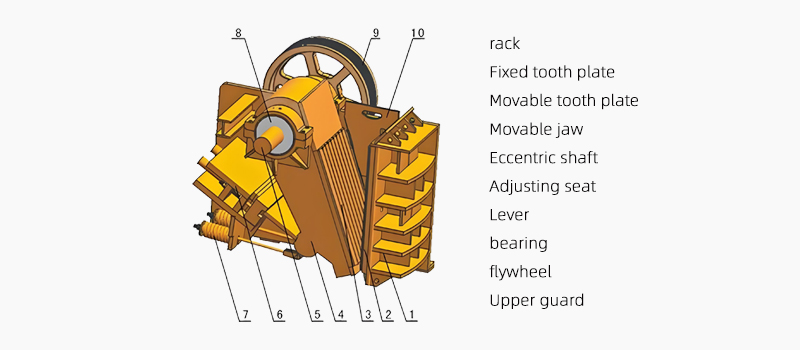

Steel plate welding jaw crusher is mainly composed of frame, working mechanism (crushing chamber), jaw plate, bearing, belt pulley, elbow plate and so on. The frame is a four-wall rigid frame with upper and lower openings that supports the eccentric shaft and withstands the reaction force of the broken material. The working mechanism is composed of a fixed jaw and a moving jaw. Both jaw plates are lined with lining plates made of manganese steel. In the crushing process, the moving jaw does reciprocating movement to squeeze and shear the material.

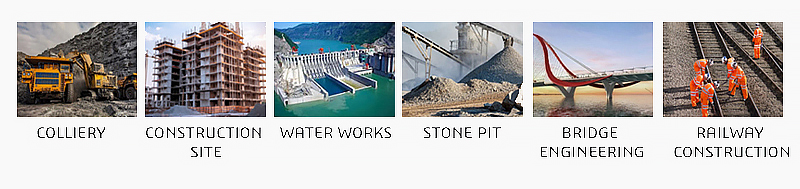

Steel plate welding jaw crusher is widely used in mining, smelting, building materials, road, railway, water conservancy and chemical industry. In these industries, it is usually used to break various ores, rocks, construction waste and other materials to facilitate subsequent processing and transportation.

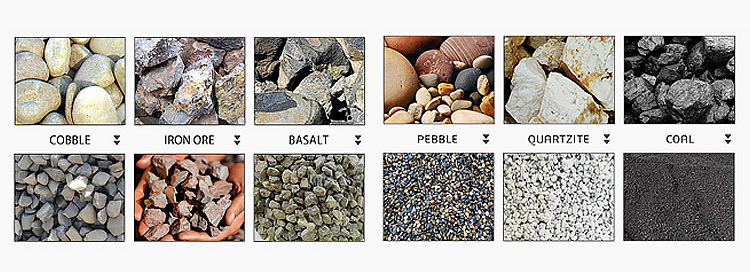

Steel plate welding jaw crusher is suitable for crushing various materials with compressive strength not exceeding 320MPa, such as limestone, granite, marble, iron ore, coal and so on. At the same time, it can also be used to break some special materials, such as cellulose board, concrete blocks of old buildings, steel waste and so on.

| Model number | Feed size (mm) | Maximum feed size (mm) | Discharge port adjustment range (mm) | Processing capacity (t/h) | Eccentric shaft speed (r/min) | Motor power (kW) | Dimensions (L × W × H) (mm) |

| PE150x250 | 150x250 | 125 | 10-40 | 1-3 | 268 | 4P 5.5 | 760x700x860 |

| PE200x300 | 200x300 | 180 | 15-50 | 2-6 | 260 | 4P 7.5 | 915x780x990 |

| PE200x350 | 200x350 | 180 | 18-60 | 3-10 | 276 | 4P 11 | 1000x914x1112 |

| PE250x400 | 250x400 | 210 | 20-70 | 5-21 | 300 | 6P 15 | 1100x1032x1285 |

| PE400x600 | 400x600 | 340 | 40-100 | 16-64 | 270 | 6P 30 | 1623x1736x1615 |

| PE500x750 | 500x750 | 425 | 50-100 | 40-110 | 268 | 6P 55 | 1920x1850x1920 |

| PE600x750 | 600x750 | 500 | 150-200 | 80-240 | 268 | 6P 55 | 2020x1850x1920 |

| PE600x900 | 600x900 | 500 | 65-160 | 50-160 | 254 | 6P 55 | 2530x1900x2340 |

| PE750x1060 | 750x1060 | 630 | 80-180 | 110-320 | 245 | 8P 110 | 2680x2380x2785 |

|

PE900x1200 |

900x1200 | 750 | 100-200 | 220-380 | 208 | 8P 110 | 3470x2876x3330 |

| PE1200x1500 | 1200x1500 | 1020 | 150-350 | 400-1000 | 180 | 8P 160-240 | 4850x3220x3680 |

| PE1500x180 | 1500x1800 | 1200 | 220-350 | 500-1200 | 180 | 8P 280-380 | 5160x3660x4248 |

| PEX150x750 | 150x750 | 120 | 18-48 | 8-25 | 320 | 4P 15 | 1170x1575x103 |

| PEX250x750 | 250x750 | 210 | 25-60 | 13-35 | 320 | 6P 22 | 1550x1730x1470 |

| PEX250x1000 | 250x1000 | 210 | 25-60 | 16-52 | 330 | 6P 30 | 1580x2006x1390 |

| PEX250x1200 | 250x1200 | 210 | 25-60 | 20-61 | 330 | 6P 37 | 1780x2214x1430 |

| PEX300x1300 | 300x1300 | 250 | 20-90 | 16-105 | 300 | 6P 55 | 2210x2320x1723 |