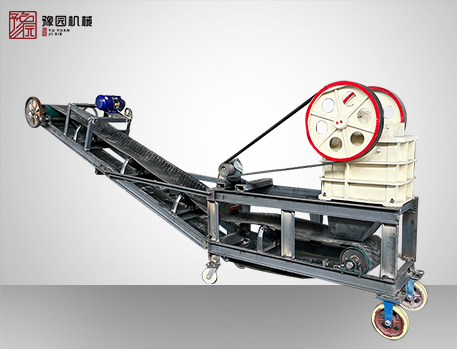

The small mobile jaw crusher, also known as the mobile jaw crusher, is a compact and powerful crushing equipment. It is mainly used for medium particle size crushing of various ores and large materials, and it is broken to medium particle size at one time.

The small mobile jaw crusher, also known as the mobile jaw crusher, is a compact and powerful crushing equipment. It is mainly used for medium particle size crushing of various ores and large materials, and it is broken to medium particle size at one time. Its structure design is light and reasonable, crushing performance is superior, product quality is reliable and stable, basically meet the requirements of coarse, medium and fine crushing.

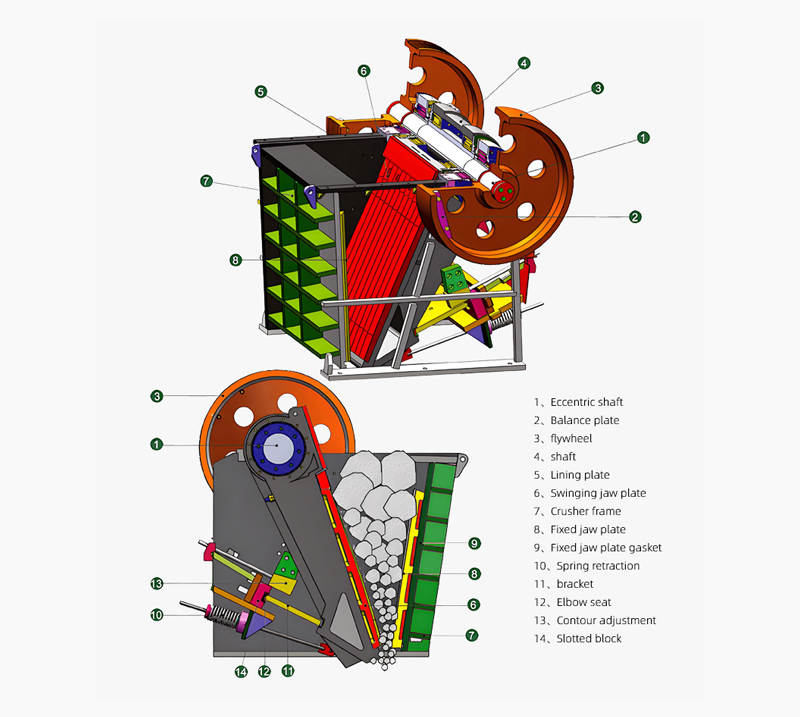

The working principle of the small movable jaw crusher mainly relies on the relative movement of two jaw plates (one fixed, one mobile). When the motor drives the belt and pulley, the movable jaw plate moves up and down through the eccentric shaft. When the movable jaw plate rises, the Angle between the movable jaw plate and the fixed jaw plate becomes larger, which pushes the movable jaw plate to the fixed jaw plate, and the material is crushed or split. When the movable jaw plate goes down, the Angle becomes smaller, the movable jaw plate leaves the fixed jaw plate under the action of the pull rod and the spring, and the broken material is discharged from the lower mouth of the crushing chamber. With the continuous rotation of the motor, the crusher can periodically crush and discharge materials to achieve the purpose of mass production.

The structure of small movable jaw crusher mainly includes fixed jaw plate, movable jaw plate, eccentric shaft, connecting rod, spring and other components. The fixed jaw plate is fixed vertically on the front wall of the body, the position of the movable jaw plate is inclined, and the fixed jaw plate forms a crushing cavity with a large upper part and a small lower part. The eccentric shaft drives the movable jaw plate to carry out periodic reciprocating movement through the connecting rod to realize the crushing of the material.

Small mobile jaw crusher is widely used in mining, smelting, building materials, road, railway, water conservancy and chemical industry. It plays an important role in concrete mixing plant, gravel yard, construction waste treatment plant and other places.

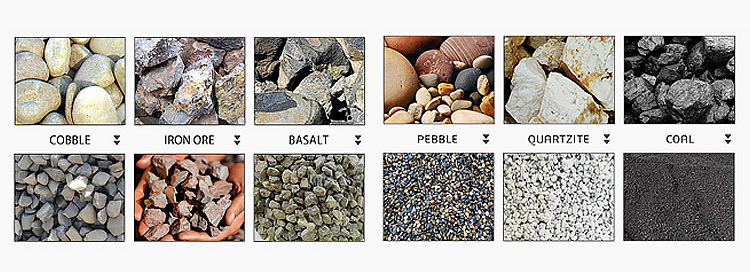

The equipment is suitable for materials with hardness of 320MPa, such as granite, limestone, river stone, basalt, diabase, ore tailings, construction waste and so on.

1. Flexible walking: The use of tire body structure design, with mobility, vehicle chassis high, small turning radius, can quickly enter the scene.

2. Combined unit configuration: Features Combined unit configuration can not only operate individual units independently, but also flexibly configure combined operations to meet various requirements such as mobile crushing and mobile screening, reducing costs.

3. Smooth walking: Adapt to a variety of complex work site conditions, can be freely driven on ordinary roads and rugged mountain roads.

4. Optimize space layout: Integrate the whole unit, reasonably compact space layout, greatly optimize the site space, eliminate the complex infrastructure and installation work of splitting components, and reduce material and man-hour consumption.

5. Dual-purpose design: Diesel generator sets can be configured to meet the needs of different customers in different working environments.

| Model number | Feed size (mm) | Maximum feed size (mm) | Discharge port adjustment range (mm) | Processing capacity (t/h) | Eccentric shaft speed (r/min) | Motor power (kW) | Dimensions (L × W × H) (mm) |

| PE150x250 | 150x250 | 125 | 10-40 | 1-3 | 268 | 4P 5.5 | 760x700x860 |

| PE200x300 | 200x300 | 180 | 15-50 | 2-6 | 260 | 4P 7.5 | 915x780x990 |

| PE200x350 | 200x350 | 180 | 18-60 | 3-10 | 276 | 4P 11 | 1000x914x1112 |

| PE250x400 | 250x400 | 210 | 20-70 | 5-21 | 300 | 6P 15 | 1100x1032x1285 |

| PE400x600 | 400x600 | 340 | 40-100 | 16-64 | 270 | 6P 30 | 1623x1736x1615 |

| PE500x750 | 500x750 | 425 | 50-100 | 40-110 | 268 | 6P 55 | 1920x1850x1920 |

| PE600x750 | 600x750 | 500 | 150-200 | 80-240 | 268 | 6P 55 | 2020x1850x1920 |

| PE600x900 | 600x900 | 500 | 65-160 | 50-160 | 254 | 6P 55 | 2530x1900x2340 |

| PE750x1060 | 750x1060 | 630 | 80-180 | 110-320 | 245 | 8P 110 | 2680x2380x2785 |

|

PE900x1200 |

900x1200 | 750 | 100-200 | 220-380 | 208 | 8P110 | 3470x2876x3330 |

| PE1200x1500 | 1200x1500 | 1020 | 150-350 | 400-1000 | 180 | 8P160-240 | 4850x3220x3680 |

| PE1500x180 | 1500x1800 | 1200 | 220-350 | 500-1200 | 180 | 8P 280-380 | 5160x3660x4248 |

| PEX150x750 | 150x750 | 120 | 18-48 | 8-25 | 320 | 4P 15 | 1170x1575x103 |

| PEX250x750 | 250x750 | 210 | 25-60 | 13-35 | 320 | 6P 22 | 1550x1730x1470 |

| PEX250x1000 | 250x1000 | 210 | 25-60 | 16-52 | 330 | 6P 30 | 1580x2006x1390 |

| PEX250x1200 | 250x1200 | 210 | 25-60 | 20-61 | 330 | 6P 37 | 1780x2214x1430 |

| PEX300x1300 | 300x1300 | 250 | 20-90 | 16-105 | 300 | 6P 55 | 2210x2320x1723 |