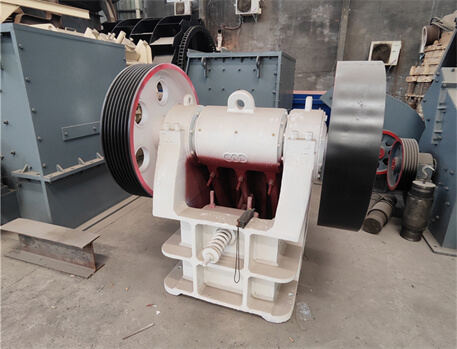

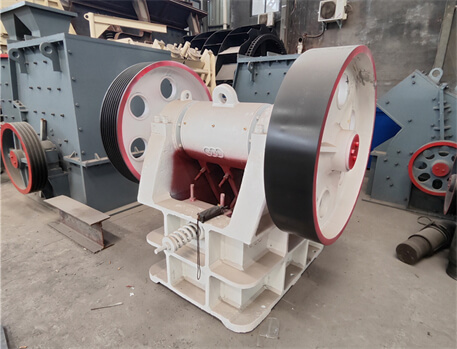

The integrated casting jaw crusher is made of high strength manganese steel, which has the advantages of wear resistance, pressure resistance and long service life. It is mainly suitable for crushing large, medium and small stones and corresponding objects, and is widely used in various industrial fields that need to be broken.

The integrated casting jaw crusher is made of high strength manganese steel, which has the advantages of wear resistance, pressure resistance and long service life. It is mainly suitable for crushing large, medium and small stones and corresponding objects, and is widely used in various industrial fields that need to be broken.

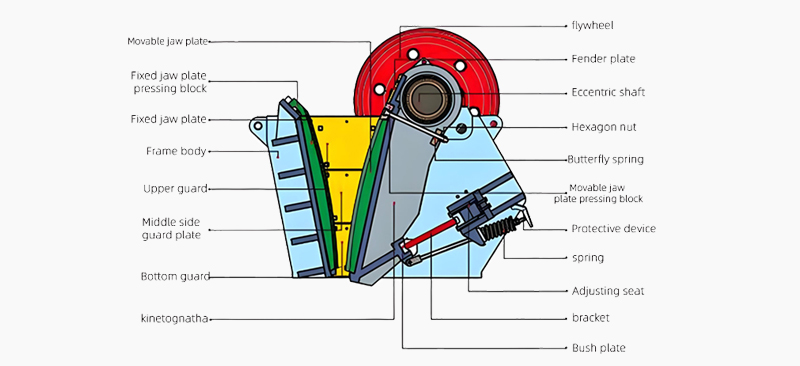

The jaw crusher breaks the material through the periodic movement of the moving jaw. In the process of swinging around the axial fixed jaw of the suspension center, the material is located between the two jaw plates and is subjected to the combined action of crushing, splitting and bending. At the beginning, the pressure is small, the material volume is reduced, and the materials are close to each other and squeezed tightly; When the pressure rises to exceed the strength that the material can withstand, the material will be broken. Each periodic movement of the moving jaw causes the material to be crushed once and sent down some distance. After a number of cycles, the broken material is discharged from the discharge port.

The integrated casting jaw crusher is mainly composed of fixed jaw plate and movable jaw plate. The movable jaw plate is connected to the drive by an eccentric shaft, allowing it to move up and down. When the movable jaw plate moves downward, the material is placed in the crushing chamber and subjected to extrusion pressure between the fixed jaw plate and the movable jaw plate. With the up and down movement of the movable jaw plate, the material gradually breaks into smaller particles. The broken material is discharged through the discharge port.

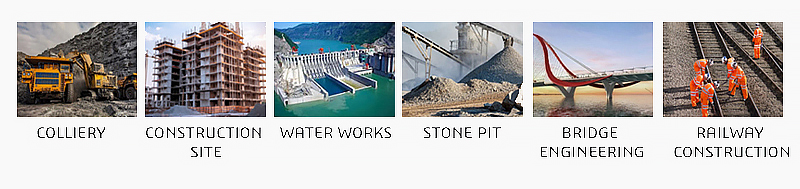

Mining industry: Due to the large raw ore, it needs to be broken during mining in order to facilitate transportation. Integrated casting jaw crusher crushing ratio is large, uniform product particle size, discharge port adjustment range is large, can meet the requirements of different users, is the ideal crushing equipment for mining various mining resources.

Construction industry: In cement production and concrete production, raw materials need to be broken to achieve the required particle size. In addition, the reuse of construction waste also requires crushing equipment. Integrated casting jaw crusher can better complete these tasks.

Road construction: The road construction industry also needs to break the materials required for road construction. The efficiency of the integrated casting jaw crusher can meet the needs of the road construction industry.

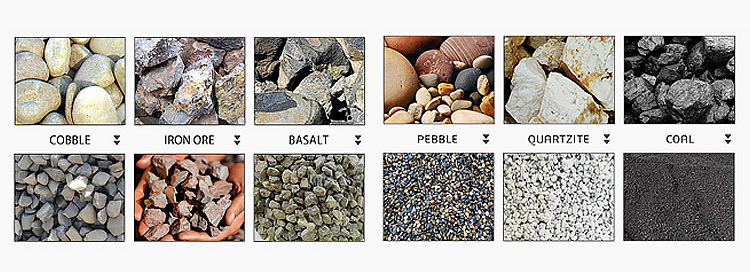

Integrated casting jaw crusher is suitable for processing a variety of particle size does not exceed 1200mm, compressive strength does not exceed 320Mpa of various materials, such as granite, quartz stone, river pebbles, calcite, concrete, dolomite, iron ore, silicon ore, basalt and other types of mines, rocks, slag and so on.

1. High efficiency: the integrated casting jaw crusher has a high crushing capacity and can quickly complete the crushing task.

2. Strong durability: The use of high strength manganese steel molding casting, with wear resistance, pressure resistance, long life and other advantages.

3. Uniform particle size: large crushing ratio, uniform product particle size, to meet the different needs of users.

4. Easy to adjust: the discharge port has a large adjustment range, and the outlet size of the crushing chamber can be adjusted according to the need to control the particle size of the product produced by the crusher.

5. Good stability: The whole machine is designed to be modular, easy to disassemble and transport. At the same time, the use of advanced moving jaw components and integrated cast steel housing makes the durability better and reduces the maintenance cost of the equipment.

| Model number | Feed size (mm) | Maximum feed size (mm) | Discharge port adjustment range (mm) | Processing capacity (t/h) | Eccentric shaft speed (r/min) | Motor power (kW) | Dimensions (L × W × H) (mm) |

| PE150x250 | 150x250 | 125 | 10-40 | 1-3 | 268 | 4P 5.5 | 760x700x860 |

| PE200x300 | 200x300 | 180 | 15-50 | 2-6 | 260 | 4P 7.5 | 915x780x990 |

| PE200x350 | 200x350 | 180 | 18-60 | 3-10 | 276 | 4P 11 | 1000x914x1112 |

| PE250x400 | 250x400 | 210 | 20-70 | 5-21 | 300 | 6P 15 | 1100x1032x1285 |

| PE400x600 | 400x600 | 340 | 40-100 | 16-64 | 270 | 6P 30 | 1623x1736x1615 |

| PE500x750 | 500x750 | 425 | 50-100 | 40-110 | 268 | 6P 55 | 1920x1850x1920 |

| PE600x750 | 600x750 | 500 | 150-200 | 80-240 | 268 | 6P 55 | 2020x1850x1920 |

| PE600x900 | 600x900 | 500 | 65-160 | 50-160 | 254 | 6P 55 | 2530x1900x2340 |

| PE750x1060 | 750x1060 | 630 | 80-180 | 110-320 | 245 | 8P 110 | 2680x2380x2785 |

|

PE900x1200 |

900x1200 | 750 | 100-200 | 220-380 | 208 | 8P 110 | 3470x2876x3330 |

| PE1200x1500 | 1200x1500 | 1020 | 150-350 | 400-1000 | 180 | 8P 160-240 | 4850x3220x3680 |

| PE1500x180 | 1500x1800 | 1200 | 220-350 | 500-1200 | 180 | 8P 280-380 | 5160x3660x4248 |

| PEX150x750 | 150x750 | 120 | 18-48 | 8-25 | 320 | 4P 15 | 1170x1575x103 |

| PEX250x750 | 250x750 | 210 | 25-60 | 13-35 | 320 | 6P 22 | 1550x1730x1470 |

| PEX250x1000 | 250x1000 | 210 | 25-60 | 16-52 | 330 | 6P 30 | 1580x2006x1390 |

| PEX250x1200 | 250x1200 | 210 | 25-60 | 20-61 | 330 | 6P 37 | 1780x2214x1430 |

| PEX300x1300 | 300x1300 | 250 | 20-90 | 16-105 | 300 | 6P 55 | 2210x2320x1723 |