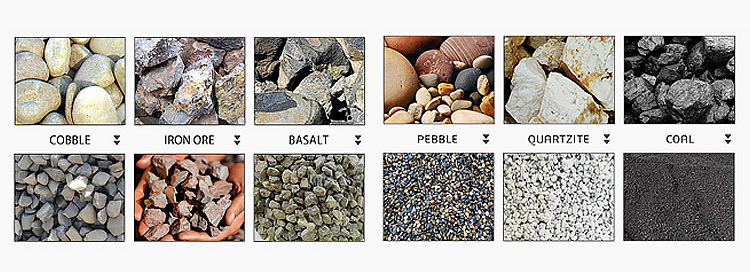

The European version jaw crusher is an advanced equipment developed for the stone crushing of highway, railway, airport runway and other engineering construction. It adopts international advanced crushing technology and manufacturing level, especially suitable for crushing ore, rock, slag with compressive strength not higher than 280Mpa, such as river pebbles, granite, basalt, iron ore, limestone, quartz stone and so on. At the same time, its feed particle size between 480-1040mm, widely used in mining, building materials, silicate, metallurgy, road construction, chemical industry raw materials and other fields, especially suitable for medium hardness material grinding, such as rock, ore, cement plant clinker and so on.

The European version jaw crusher is an advanced equipment developed for the stone crushing of highway, railway, airport runway and other engineering construction. It adopts international advanced crushing technology and manufacturing level, especially suitable for crushing ore, rock, slag with compressive strength not higher than 280Mpa, such as river pebbles, granite, basalt, iron ore, limestone, quartz stone and so on. At the same time, its feed particle size between 480-1040mm, widely used in mining, building materials, silicate, metallurgy, road construction, chemical industry raw materials and other fields, especially suitable for medium hardness material grinding, such as rock, ore, cement plant clinker and so on.

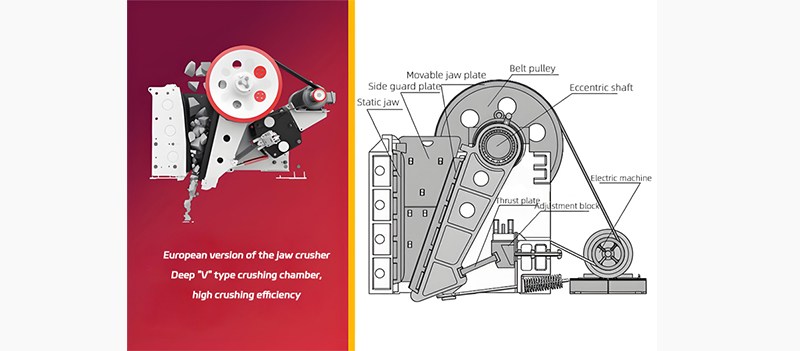

The working principle of the jaw crusher is to use the extrusion and friction between the jaw plate and the fixed jaw and the moving jaw to crush the material. The material is placed in an adjustable feed port and then pressed between two moving jaw plates. The jaw plate on one side is fixed, and the jaw plate on the other side moves under the action of an eccentric shaft, thus crushing the material. Through the up and down movement of the boom, the material fixed in the jaw plate between the jaw bottom and the jaw frame is squeezed, rubbed and hit, and then broken into the required particle size.

The main structure of the jaw crusher includes the frame part, the eccentric shaft rotation part, the crushing chamber working part, the safety device and the discharge port adjustment device. The frame part is composed of side plate, front box assembly, rear box weldment, etc. The rotating part of eccentric shaft is mainly composed of moving jaw, eccentric shaft, bearing, bearing seat, belt pulley, etc. The working part of the crushing chamber is mainly composed of a fixed jaw plate, a moving jaw plate, a side lining plate, a protection plate, etc. The safety device is composed of elbow plate, elbow plate seat, spring, spring pull rod, etc. The adjusting device of the discharge port is mainly composed of adjusting fixed skew block, adjusting sliding skew block, wire bolt and sliding block locking rod.

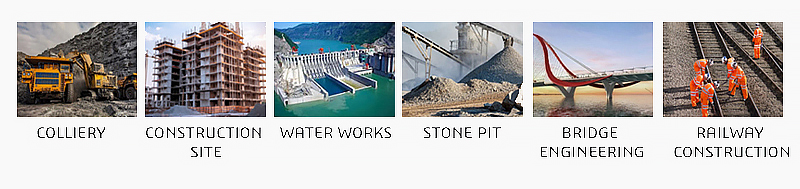

Eurotype jaw crusher is widely used in mining, metallurgy, building materials, road, railway, water conservancy and chemical industry and other industries. It is mainly used in metallurgy, mining, chemical industry, cement, construction, refractory materials and ceramics and other industrial sectors for medium and fine crushing of various medium hard ores and rocks.

Jaw crusher is suitable for crushing ore, rock, slag with compressive strength not higher than 280Mpa, as well as river pebbles, granite, basalt, iron ore, limestone, quartz stone and other materials.

1. Bearing seat adopts integral cast steel structure to ensure complete coordination with crushing frame and greatly enhance the radial strength of bearing seat.

2. The crushing chamber adopts a symmetrical "V" shape structure to ensure that the actual inlet width is consistent with the nominal inlet width and effectively increase the crushing area.

3. It is equipped with wedge discharge port adjustment device, which makes adjustment more simple, safe and fast.

4. The effective length of the jaw plate can be increased and the yield can be increased by using the toothed guard plate.

5. Hydraulic control, easy cavity cleaning, reduce downtime.

| Model number | Feed size (mm) | Maximum feed size (mm) | Discharge port adjustment range (mm) | Processing capacity (t/h) | Eccentric shaft speed (r/min) | Motor power (kW) | Dimensions (L × W × H) (mm) |

| PE150x250 | 150x250 | 125 | 10-40 | 1-3 | 268 | 4P 5.5 | 760x700x860 |

| PE200x300 | 200x300 | 180 | 15-50 | 2-6 | 260 | 4P 7.5 | 915x780x990 |

| PE200x350 | 200x350 | 180 | 18-60 | 3-10 | 276 | 4P 11 | 1000x914x1112 |

| PE250x400 | 250x400 | 210 | 20-70 | 5-21 | 300 | 6P 15 | 1100x1032x1285 |

| PE400x600 | 400x600 | 340 | 40-100 | 16-64 | 270 | 6P 30 | 1623x1736x1615 |

| PE500x750 | 500x750 | 425 | 50-100 | 40-110 | 268 | 6P 55 | 1920x1850x1920 |

| PE600x750 | 600x750 | 500 | 150-200 | 80-240 | 268 | 6P 55 | 2020x1850x1920 |

| PE600x900 | 600x900 | 500 | 65-160 | 50-160 | 254 | 6P 55 | 2530x1900x2340 |

| PE750x1060 | 750x1060 | 630 | 80-180 | 110-320 | 245 | 8P 110 | 2680x2380x2785 |

|

PE900x1200 |

900x1200 | 750 | 100-200 | 220-380 | 208 | 8P 110 | 3470x2876x3330 |

| PE1200x1500 | 1200x1500 | 1020 | 150-350 | 400-1000 | 180 | 8P 160-240 | 4850x3220x3680 |

| PE1500x180 | 1500x1800 | 1200 | 220-350 | 500-1200 | 180 | 8P 280-380 | 5160x3660x4248 |

| PEX150x750 | 150x750 | 120 | 18-48 | 8-25 | 320 | 4P 15 | 1170x1575x103 |

| PEX250x750 | 250x750 | 210 | 25-60 | 13-35 | 320 | 6P 22 | 1550x1730x1470 |

| PEX250x1000 | 250x1000 | 210 | 25-60 | 16-52 | 330 | 6P 30 | 1580x2006x1390 |

| PEX250x1200 | 250x1200 | 210 | 25-60 | 20-61 | 330 | 6P 37 | 1780x2214x1430 |

| PEX300x1300 | 300x1300 | 250 | 20-90 | 16-105 | 300 | 6P 55 | 2210x2320x1723 |