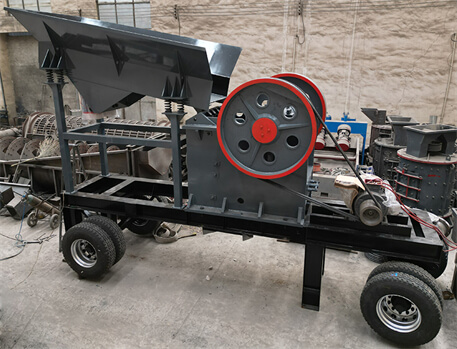

Mobile jaw crusher, also known as mobile crushing station, is a new type of rock breaking device, which greatly expands the scope of application of the crusher. It integrates the feeder and vibrating screen with the crusher, the on-board installation of the belt conveyor, vibrating screen and crusher, and the steering traction shaft is convenient for road transportation and site depth.

Mobile jaw crusher, also known as mobile crushing station, is a new type of rock breaking device, which greatly expands the scope of application of the crusher. It integrates the feeder and vibrating screen with the crusher, the on-board installation of the belt conveyor, vibrating screen and crusher, and the steering traction shaft is convenient for road transportation and site depth. This equipment eliminates the complex site infrastructure installation work of separate components, reduces the consumption of materials and man-hours, and improves the flexibility of the site.

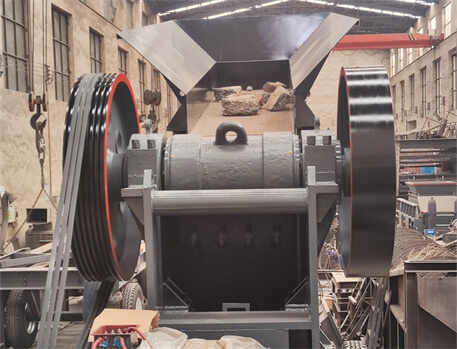

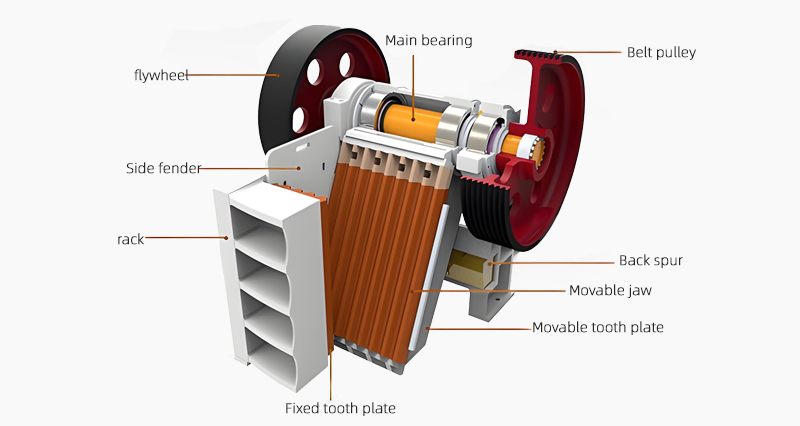

The jaw crusher breaks the material through the periodic movement of the moving jaw. In the process of swinging around the axial fixed jaw of the suspension center, the material is located between the two jaw plates and is subjected to the combined action of crushing, splitting and bending. At the beginning, the pressure is small, the material volume is reduced, and the materials are close to each other and squeezed tightly; When the pressure rises to exceed the strength that the material can withstand, the material will be broken. Each periodic movement of the moving jaw causes the material to be crushed once and sent down some distance. After a number of cycles, the broken material is discharged from the discharge port.

Mobile jaw crusher is mainly composed of frame, jaw plate, eccentric shaft, rocker arm, adjustment device and other components. Jaw plates are usually made of high manganese steel with good wear resistance. When the eccentric shaft rotates, the rocker arm drives the jaw plate to move, so that the material is sandwiched between the two jaw plates, and then breaks the material through the friction and impact of the jaw plate. The broken material is discharged from the discharge port.

Mobile jaw crusher is widely used in metallurgy, mining, building materials, highway, railway, water conservancy, chemical industry, cement, construction, refractory materials and ceramics and other industries. In particular, it is used in mines, coal mines, garbage and construction waste recycling, as well as earthwork, municipal infrastructure, roads or construction sites.

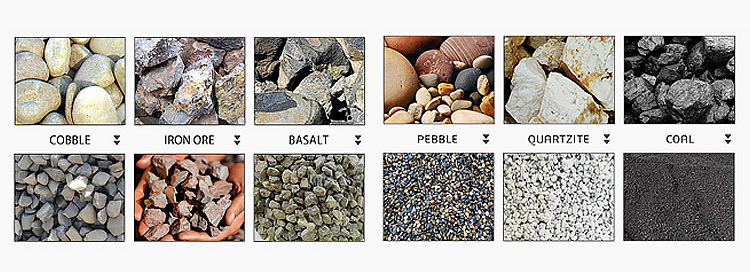

The mobile jaw crusher is suitable for crushing all kinds of soft and hard ores with compressive strength not exceeding 320 mpa, such as river pebbles, mountain stones (limestone, granite, basalt, diabase, andesite, etc.), ore tailings, stone chips, etc. In addition, it can also be used for construction waste treatment, thermal power plant raw material treatment, iron ore primary crushing and so on.

1. High efficiency: high efficiency, meet the requirements of coarse, medium and fine crushing.

2. Flexibility: The use of tire body structure design, the vehicle chassis is high, the turning radius is small, easy to travel freely on ordinary roads and rugged mountain roads, and quickly enter the scene.

3.Convenience: The installation form of integrated unit equipment eliminates the complex site infrastructure installation work of separate components, and reduces the consumption of materials and working hours.

4. Reliability: The structure design is light and reasonable, the crushing performance is superior, and the product quality is reliable and stable.

5. Diversity: Feature combination unit configurations allow not only independent operation of individual units, but also flexible configuration of combined operations to meet various requirements such as mobile crushing and mobile screening.

6. Adaptability: oil-electric dual-purpose design, diesel generator set can be configured to meet the needs of different customers in different working environments.

| Model number | Feed size (mm) | Maximum feed size (mm) | Discharge port adjustment range (mm) | Processing capacity (t/h) | Eccentric shaft speed (r/min) | Motor power (kW) | Dimensions (L × W × H) (mm) |

| PE150x250 | 150x250 | 125 | 10-40 | 1-3 | 268 | 4P 5.5 | 760x700x860 |

| PE200x300 | 200x300 | 180 | 15-50 | 2-6 | 260 | 4P 7.5 | 915x780x990 |

| PE200x350 | 200x350 | 180 | 18-60 | 3-10 | 276 | 4P 11 | 1000x914x1112 |

| PE250x400 | 250x400 | 210 | 20-70 | 5-21 | 300 | 6P 15 | 1100x1032x1285 |

| PE400x600 | 400x600 | 340 | 40-100 | 16-64 | 270 | 6P 30 | 1623x1736x1615 |

| PE500x750 | 500x750 | 425 | 50-100 | 40-110 | 268 | 6P 55 | 1920x1850x1920 |

| PE600x750 | 600x750 | 500 | 150-200 | 80-240 | 268 | 6P 55 | 2020x1850x1920 |

| PE600x900 | 600x900 | 500 | 65-160 | 50-160 | 254 | 6P 55 | 2530x1900x2340 |

| PE750x1060 | 750x1060 | 630 | 80-180 | 110-320 | 245 | 8P 110 | 2680x2380x2785 |

|

PE900x1200 |

900x1200 | 750 | 100-200 | 220-380 | 208 | 8P 110 | 3470x2876x3330 |

| PE1200x1500 | 1200x1500 | 1020 | 150-350 | 400-1000 | 180 | 8P 160-240 | 4850x3220x3680 |

| PE1500x180 | 1500x1800 | 1200 | 220-350 | 500-1200 | 180 | 8P 280-380 | 5160x3660x4248 |

| PEX150x750 | 150x750 | 120 | 18-48 | 8-25 | 320 | 4P 15 | 1170x1575x103 |

| PEX250x750 | 250x750 | 210 | 25-60 | 13-35 | 320 | 6P 22 | 1550x1730x1470 |

| PEX250x1000 | 250x1000 | 210 | 25-60 | 16-52 | 330 | 6P 30 | 1580x2006x1390 |

| PEX250x1200 | 250x1200 | 210 | 25-60 | 20-61 | 330 | 6P 37 | 1780x2214x1430 |

| PEX300x1300 | 300x1300 | 250 | 20-90 | 16-105 | 300 | 6P 55 | 2210x2320x1723 |